Uranium mine moving closer to production

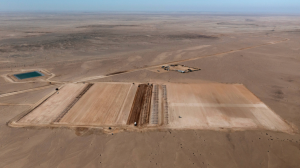

Bannerman Energy CEO Gavin Chamberlain discusses the company’s Namibia-based Etango uranium project with Engineering News.

SIGNIFICANT PRODUCTION The Etango mine is projected to produce about 3.5-million pounds of uranium yearly through an opencast mining method

The Namibia-based Etango uranium project of Australian uranium development company Bannerman Energy is advancing towards production, with first uranium output expected in 2028.

The project is set to bolster Namibia’s position as one of the world’s leading uranium producers, adding to the country’s existing uranium operations at Rossing, Husab and the recently reopened Langer Heinrich mines.

Considering that Namibia is currently the third-largest uranium producer globally, Bannerman CEO Gavin Chamberlain says the addition of Etango is expected to strengthen the country’s ranking.

The mine is projected to produce about 3.5-million pounds (or more than 1.58-million kg) of uranium yearly through an opencast mining method.

Etango’s processing method also sets it apart from legacy uranium mines in Namibia, as it will use a heap leach process, whereas Namibia’s other uranium mines primarily use tank leaching.

According to Chamberlain, the project represents a significant milestone not just for the company but for Namibia’s broader mining sector.

“The fact that we will be the fourth uranium mine in Namibia is a big achievement and keeps Namibia right at the top of the global uranium industry,” he says.

As Bannerman moves towards full-scale construction at Etango, the company has reached several milestones – one of the most significant being the company’s granting of a mining licence in December 2023, following an application process that started in August 2022.

This approval enables the company to accelerate project development, as securing a mining licence is a prerequisite for obtaining major funding.

In anticipation of the licence, Bannerman had already started front-end engineering design work, refining the project’s engineering and cost estimates.

The company also re-tendered contracts to ensure accurate pricing before advancing to the construction phase.

Following the approval, Bannerman awarded its first two construction contracts in December 2023, covering the installation of a pipeline to supply construction water and the development of an access road connecting the project site to the main road.

Both were completed by mid-2024, establishing the foundation for the next phases of development.

A key financial milestone was the successful completion of an A$85-million fundraising round in June 2024, which enables the company to proceed with further early works and also enables Bannerman to award contracts for additional infrastructure, including internal access roads, bulk earthworks and construction power supply.

The bulk earthworks phase, which is critical for preparing the site for key processing infrastructure, is expected to be completed by 2026.

Bannerman is targeting uranium production by 2028 and with commissioning scheduled for 2027, the company has implemented a structured stage gate process, which involves quarterly board updates to assess progress and approve new contract placements.

The structured stage gate approach allows the company to balance financial discipline with steady construction momentum.

This is meant to ensure the project remains on track and ensures that construction momentum is maintained while identifying and mitigating potential risks, Chamberlain tells Mining Weekly.

Key Obstacle Addressed

One such challenge is water availability – a key consideration in Namibia’s mining industry.

Recognising this early on in the project work, Chamberlain explains the company took proactive steps to address the issue through constructing a dedicated water supply pipeline before major construction started. The company also built a large onsite reservoir with a storage capacity of 9 000 m3, thereby enabling construction to continue even if water supply disruptions occur.

Chamberlain emphasises that these pre-emptive measures have already proven effective.

“Namibia’s desalination plant experienced a planned shutdown in November, but we were able to continue work without any delays because of our onsite water storage. Similarly, a recent sulphur bloom led to another shutdown, but again, we had sufficient reserves to continue operations,” he says.

Bannerman has also prioritised localisation, using Namibian contractors, with all five major construction contracts awarded to local firms.

Chamberlain highlights the benefits of this approach, including cost efficiency and the ability to work with experienced contractors familiar with mining operations.

Many of these companies were involved in recent upgrade projects at Langer Heinrich, he adds, pointing out that this means they already meet the high safety and quality standards required for uranium mining.

To further facilitate local participation, Bannerman has structured its contracts into smaller, more manageable packages, enabling Namibian firms to compete effectively, as many local companies lack the capacity to independently take on large-scale projects.

“The integration of Namibian contractors into our project has been a major success. Not only does it strengthen the local economy by keeping funds within Namibia, but it also simplifies logistics and supervision. We don’t need to bring in international teams to oversee the work when we have qualified local contractors available,” Chamberlain explains.

While the workforce currently fluctuates depending on project requirements, the site has already seen up to 200 workers employed at various stages of construction. As activity ramps up, employment is expected to peak at about 1 500 workers.

Market Positioning

Alongside its construction efforts, Bannerman is focusing on securing the necessary financing and uranium offtake agreements. The company is pursuing a dual funding strategy and exploring both traditional debt financing, as well as possibly bringing in a strategic partner.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation