Local capacity embeds Weir solutions in West Africa

Andrew Ayirebi, Regional Manager for West Africa at Weir

Weir’s ENDURON® HPGRs achieve energy savings of up to 40% compared with traditional SAG mill technology

GEHO® positive displacement pumps from Weir minimise energy consumption when transporting slurry over long distances

Weir’s NEXT intelligent solutions provide mine operators with real-time insights into equipment condition and performance

Weir develops local technical capacity and expertise to ensure meaningful support for surrounding communities

In partnership with customers, Weir ensures every product delivered performs at its best

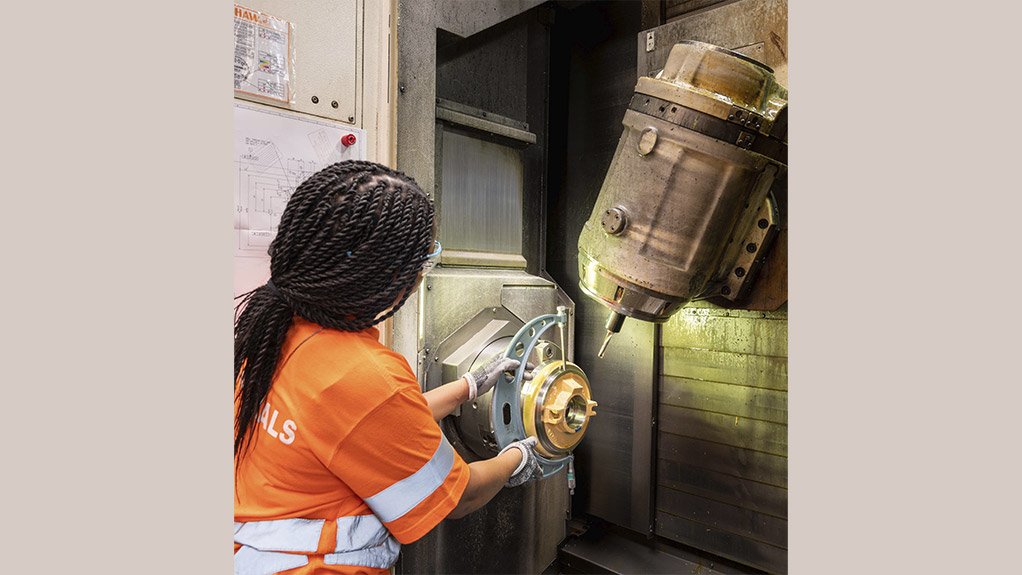

Weir’s commitment to equality, inclusion and diversity drives the development of a broad range of technical skills across all its sites

This article has been supplied.

With West Africa’s mining industry evolving rapidly, Weir has built a solid footprint of local expertise, capability and capacity in the region - to serve customers’ increasing demand for efficiency, sustainability and technological integration.

“Weir has proactively invested in training and skills development to build talent to meet operational demands in the region,” Andrew Ayirebi, Weir's Regional Manager for West Africa, explains. “This commitment ensures seamless service delivery, regardless of where our customers are located.”

The development of local technical capability has become crucial as the region’s mining sector embraces the need for local economic development while increasingly expecting OEMs to operate in close proximity to their operations.

“In line with Weir’s philosophy of thinking globally and acting locally, we prioritise developing our people - who are key to delivering sustainable value,” Ayirebi says. “Our operations in Ghana and Senegal are fully managed by local teams, with an active presence in Mali, Côte d'Ivoire and Nigeria.”

With its focus on customised solutions, Weir supports a wide range of commodities mined in West Africa including gold, bauxite, iron ore and lithium. The company is strategically transitioning to configured-to-order (CTO) systems to further reduce lead times while improving efficiency and stability of supply chains.

“We partner with customers throughout the mining lifecycle, supporting our sustainable mining and processing solutions with on-site services and fast response times,” he says. He points to the wide range of operational areas where Weir adds value which includes comminution, classification, slurry handling and dewatering.

“In terms of comminution, grinding is one of the most energy intensive steps in mining,” he explains. “Our ENDURON high-pressure grinding roll (HPGR) technology reduces energy consumption in comminution applications, saving up to 40% in energy consumption compared to traditional SAG mill technology.”

At Endeavour’s Lafigué open pit gold mine in north-central Côte d’Ivoire, for instance, Weir provided its HPGR technology to save energy and reduce the carbon footprint – alongside consuming less grinding media – to achieve lower operating costs and ensure a more consistent throughput. The ENDURON® HPGR has delivered an operating availability of over 97%, and will enable the mine to achieve US$2,6 million in energy savings each year. This equates to avoiding the emission of 18,500 tonnes of CO2 emissions per year.

Investing heavily in R&D, Weir also enhances equipment with its WRT® which reduces energy usage in its WARMAN® pumping systems, for instance. The GEHO® range of positive displacement pumps, which transport high density slurries over long distances, also minimise energy consumption.

Weir’s classification solutions ensure optimal particle size distribution to maximise the efficiency of downstream processes. Weir also leverages digital technology to further enhance the value of its equipment, by applying its NEXT intelligent solutions.

“This gives mining operators real-time insights into equipment condition and performance,” says Ayirebi. “Our acquisition of digital mining solutions leader Micromine earlier this year further strengthens our ability to optimise customers’ operations.”

He highlights Weir’s vision that mining must go beyond mineral extraction - to embrace safe, responsible and environmentally sustainable practices. This is as relevant in West Africa, he says, where the focus is on helping customers to deliver natural resources efficiently and sustainably.

Weir’s commitment to equality, inclusion and diversity drives the development of a broad range of technical skills across all its sites.

Weir Minerals Africa

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation