Used oil recycling important for explosives

USED OIL END PRODUCT It is possible to recover value from a product once it has reached the end of its life through recycling and reuse

USED OIL COLLECTION TRUCK Given the logistics involved in collecting used oil from suppliers, risk management is a primary consideration

EMILIA MASCIS BME follows a ‘cradle-to-cradle’ approach when it comes to the remanufacturing of old oil

The use of recycled fuel oil as a key ingredient in ammonium nitrate-based explosives is an accepted practice in the local explosives industry. However, few users of the explosives give much thought to the processes that are involved in collecting, transferring and transforming the used oil in an environment- friendly manner, says mining explosives supplier BME.

“Simply disposing of or destroying used oil does not add value to the waste product. It is still possible to recover value from a product once it has reached the end of its life through recycling and reuse,” highlights BME used oil manager Emilia Mascis.

She adds that the used oil division at BME has been awarded contracts both in South Africa and Africa to collect waste oil from major coal, diamond and copper mining projects, as well as other nonrelated industries since the early 1980s.

The ‘cradle-to-cradle’ philosophy is the concept of preparing waste oil for reuse by handling waste oil on behalf of clients and providing environmental storage facilities for customers’ sites.

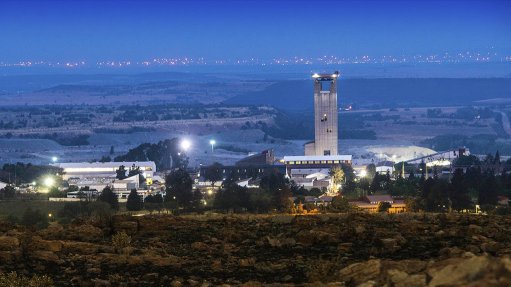

Once the used oil is stored in a designated storage container, it is transported in tankers to BME’s Dryden emulsion plant, in Losberg, Gauteng, where the waste is treated and used as a fuel agent in BME’s explosives.

“Given the logistics involved in collecting used oil from suppliers – some of them across South Africa’s borders – the management of risk is a primary consideration. “This involves comprehensive measures that transcend road tankers and includes ensuring that our drivers are knowledgeable about their loads and that steps are taken along the value chain from collection to manufacturing of the explosives to ensure that safety and quality is maintained,” says Mascis.

She adds that many manufacturers say they follow ‘cradle-to-grave’ processes when they describe how they collect and use materials. BME, however, follows a ‘cradle-to- cradle’ approach.

“Instead of processing and then disposing of the product, we transform it. The old oil is recreated in a new form, enabling it to fulfil a new purpose in its life cycle.”

Mascis says BME is conscious of the potential of its key product ingredient to pollute soil and water, which is why the company institutes stringent measures to ensure that the handling of oil is conducted safely and adheres to green principles.

“Membership of industry bodies established for safe handling of the product is just one part of the process. Suppliers’ facilities and storage tanks, as well as the oil, are also checked by BME for quality purposes. This process includes examining the type of oil the supplier uses before it has been processed, so that we can ascertain if it is mineral-based, or synthetic.”

BME compares this information with the product data sheet, enabling the company to look for any sign of contamination. A sample of the oil is sent to the Losberg laboratory plant for testing.

Mascis adds that all BME road tankers adhere to legislation and regulations governing the transport of dangerous materials by road, such as the National Road Traffic Act and SANS 10231:2010 operational requirements for road vehicles transporting dangerous goods.

She also points out that all the company’s vehicles are examined and audited by the relevant companies and organisations, such as the nonprofit administrator for the collection, storage and recycling of used oil, the Recycling Oil Saves the Environment Foundation and freight transportation consultant Transheq Consulting, to ensure that they meet the required standards.

In terms of logistics quality control, Mascis states that all BME drivers are qualified to transport their loads.

“Our drivers have been trained to examine oil at sites to determine what additives have been included. “The addition of petrol waste or paraffin, for example, is dangerous as it lowers the flashpoint of the mixture,” she says, adding that drivers are trained and certified in Hazchem regulations, which includes spill response, emergency response, firefighting and first aid.

Mascis adds that the company’s cradle-to- cradle philosophy moves past the concept of achieving the minimum requirements of treatment or disposal, through the manufacture of a new raw material for explosives.

She emphasises that, by employing this philosophy, many mining groups can add value to an otherwise hazardous product.

“Our aim with used oil is not to dispose of it in landfills or other sites, but to reprocess it and create a new product. This is recycling in the true sense,” Mascis concludes.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation