Valves supplier highlights importance of technical knowledge

LEAVING FOOTPRINTS Stewarts and Lloyds’ footprint expands throughout Africa and globally, enabling the company to reach a wider client base in various industries

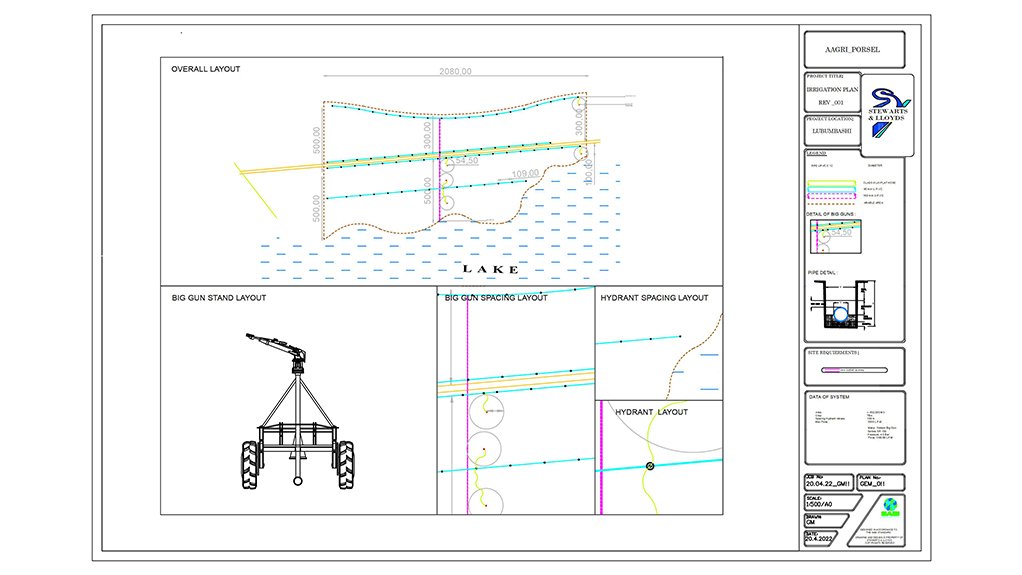

PROJECTS UNDERWAY Stewarts and Lloyds is designing and installing various valves for fluid handling projects

A holistic approach should be followed when buying valves to ensure that they are appropriate for specific applications, says valves and steel supplier Stewarts and Lloyds export manager Andre Swart.

“There has been a huge drive in South Africa’s fluid handling and irrigation industry where quality is now being emphasised over price. Over the next few years, water is going to be one of the most highly sought-after commodities and people understand that the valves they install should last 20 or even 30 years,” adds Stewarts and Lloyds sales manager Gareth Manson.

While there are many new valves suppliers in the market, Stewarts and Lloyds sales manager Leanne Webster says valves supplied may not necessarily be suited to the required application.

Additionally, buying valves online has altered companies’ buying strategies, thereby causing price sensitivity and stockholding volatility, owing to buyers’ being misinformed and lacking in field experience.

Stewarts and Lloyds sales representative Mohammed Ismail adds that, when buying brass products online, brass specifications can be inadequate for the valves, causing them to crack when installed or tightened.

While brass is more cost effective, Ismail cautions that lower-grade metal in valves can cause them to rust and erode quicker.

“Many metals and materials used to make valves barely meet the specification standards, whereas our valves exceed the standards.”

Skills Development

Webster adds that, owing to misinformation and lack of technical skills, buyers are often hesitant to buy newer valves that are more suitable for the applications than older valves.

Hence, Stewarts and Lloyds trains its staff and equips them with a better understanding of suitable suppliers that can meet client demands. Employees are also trained to understand the relevant terminology and product specifications to assist clients.

Swart says the company aims to provide quarterly training to update staff on new products.

With 32 branches, the company’s footprint expands throughout Africa and globally, consequently enabling the company to reach a wider client base in various industries, including water and petrochemicals.

The company aims to further expand its footprint and service more industries to become a household name that clients can rely on.

“Our extensive footprint enables us to source best materials at a competitive market price for our clients because we have multiple suppliers. We are a one-stop shop offering quality assurance and expertise, and we source materials globally, which makes us competitive in a market that is experiencing a product shortage,” comments Manson.

Projects

Stewarts and Lloyds is designing and installing different valves for fluid handling projects.

The company plays a role in specifying the correct valves for the correct applications.

The company supplies valves for several projects and will be assisting municipalities affected by floods in KwaZulu-Natal by replacing the necessary valves and assisting with technical needs.

The company is also working on valve-related projects in wider Africa, for residential and industrial areas, as well as on an artificial sports field in Mozambique.

Stewarts & Lloyds supplies valves along with entire systems accompanying the valves.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation