Versatile cam clutches ensure broad application

SAFETY FIRST Tsubaki backstop cam clutches, which are designed for safety in high- or low-speed applications, meet the requirements of the Mine Health and Safety Act

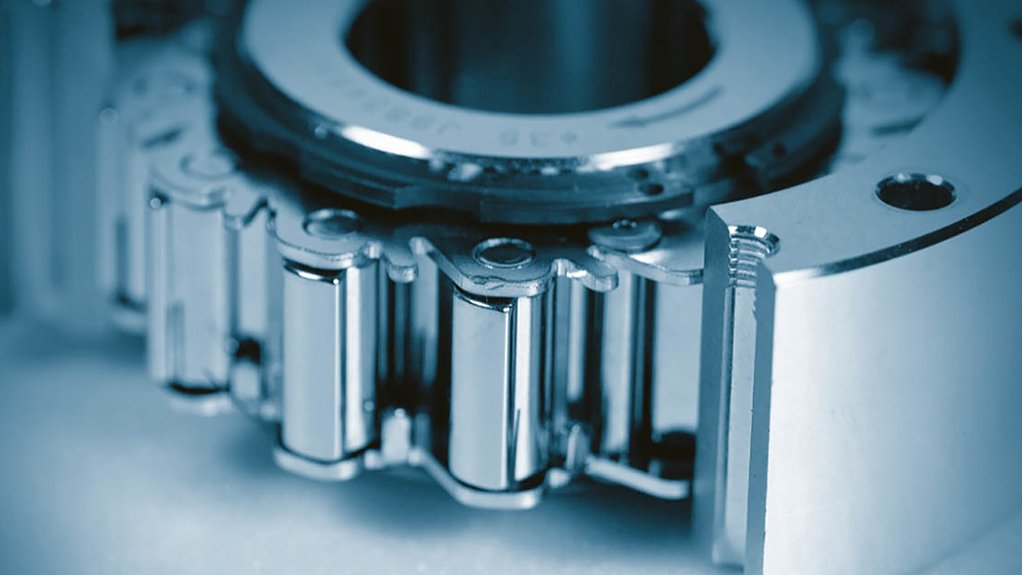

FIT FOR PURPOSE BMG’s range of Tsubaki cam clutches comprises is designed for use in equipment that includes inclined conveyors and bucket elevators

Engineering components provider BMG’s range of Tsubaki cam clutches comprises the backstop reducer high-torque (BR-HT) series, designed for use in equipment that includes inclined conveyors and bucket elevators.

These backstop cam clutches offer optimised speed overrunning and higher torque than conventional cam clutches to prevent the reverse rotation of drive shafts, consequently avoiding damage to machinery and expensive equipment while enhancing safety.

The BR-HT series – available from the company in a selection of 65 units, with bore sizes from 20 mm to 320 mm – provides torque capacities from 105 Nm to 366 000 Nm and maximum overrunning speeds from 1 000 rpm to 3 600 rpm.

These robust cam clutches, ideal for original-equipment manufacturer applications, have a special integrated design of centrifugal lift-off cams that provide mechanical engagement only when needed, with no contact between cams and races, says BMG power transmission division product specialist Chase Swaffield.

“At all other times, the cam clutch rotates freely, with no mechanical contact in the clutch mechanism. The advantage of this noncontact operation is extended service life.

“The design of the BR-HT clutch series features a full complement of cams to provide the maximum number of load-transmitting members per given diameter. This results in greater torque capacity, size for size, compared with other types of one-way clutches.”

The simple design, in which the cam clutch mechanism is incorporated in a cage between standard-dimension inner and outer bearing races, enables the cam clutch to be easily integrated into a wide range of mechanical systems.

The facility for this type of mounting is further enhanced with a keyway that simplifies installation by ensuring positive location and fixing of the clutches onto shafts.

Meanwhile, with the outer race of the clutch anchored to a stationary member, the inner race can overrun freely in one direction of rotation, even at high speed, he notes.

Additionally, reverse rotation is instantaneously prevented by the automatic engagement of the clutch.

Further, the Mine Health and Safety Act states that the installation of inclined conveyor belts must include the fitting and use of one or more devices to prevent run-back or run-on, to avert injury by materials or minerals falling from a conveyor belt.

Swaffield highlights that the Tsubaki backstop cam clutches, which are designed for safety in high- or low-speed applications, meet the requirements of the Act.

BMG’s technical team advises on the selection of the correct cam clutch for each application and the appropriate installation and use for optimum performance and improved safety standards.

For extended service life, correct lubrication methods and dust prevention care are also critical, he concludes.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation