Welding Alloys South Africa

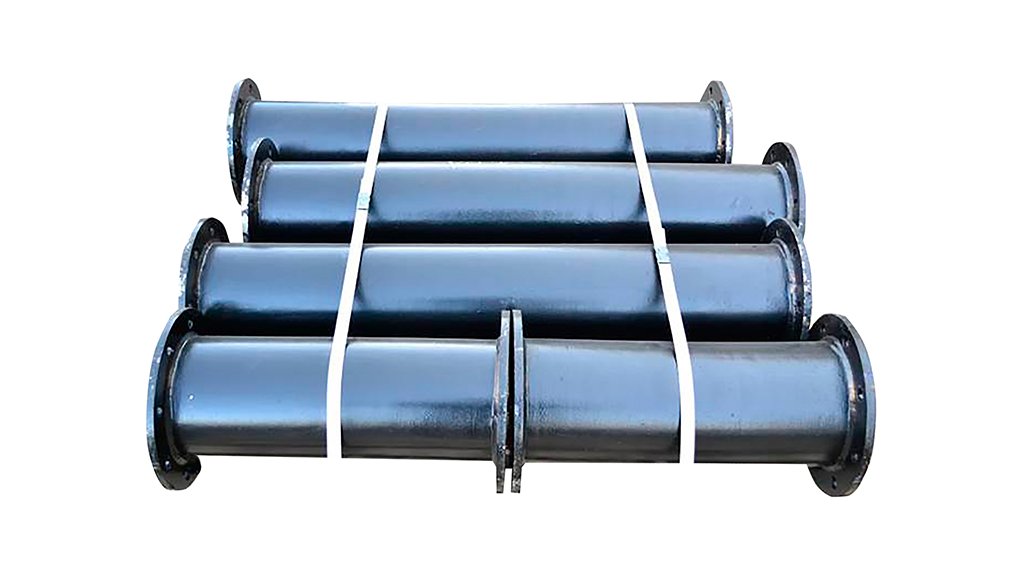

As one of the market leaders in providing engineered solutions to combat wear, welding consumables manufacturer Welding Alloys South Africa (WASA) has been manufacturing welded composite overlay material since 1976. Employing eight automated welding stations, WASA is currently one of the largest producers of these products in the southern hemisphere.

Its Hardplate range is made up of six different materials, all with unique features ideally suited to specific areas of application. These range from standard chromium carbide (Cr-C) material to complex carbide and impact-resistant materials.

The company notes that its Hardplate 100S is considered to be its workhorse of materials. This Cr-C welded overlay plate is locally produced in various thicknesses, ranging from (3+3) 6mm- up to (12+12) 24-mm-thick plates. These are supplied in either full sheets or cut-to-size products.

Besides supplying flat products, value-added fabrication is also done at WASA’s ISO 3834-certified plant in Apex, Benoni. In comparative normal abrasive wear applications, Hardplate 100S will conservatively outlast quenched and tempered material by five to seven times, resulting in much lower costs of ownership.

Tuffplate S is a lower hardness welded overlay product with outstanding impact resistance. It is one of the very few products globally that is able to resist both extreme abrasion combined with high levels of impact in a single product.

It is very successfully used in applications where severe abrasion is combined with extremely high impact levels, such as the beds of large haul truck bins used in the mining industry. This unique product bridges the gap that previously existed in industry, where suppliers could completely address either abrasion or impact, but never both wear mechanisms by using one product. Thanks to Tuffplate S, those problems belong to the past.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation