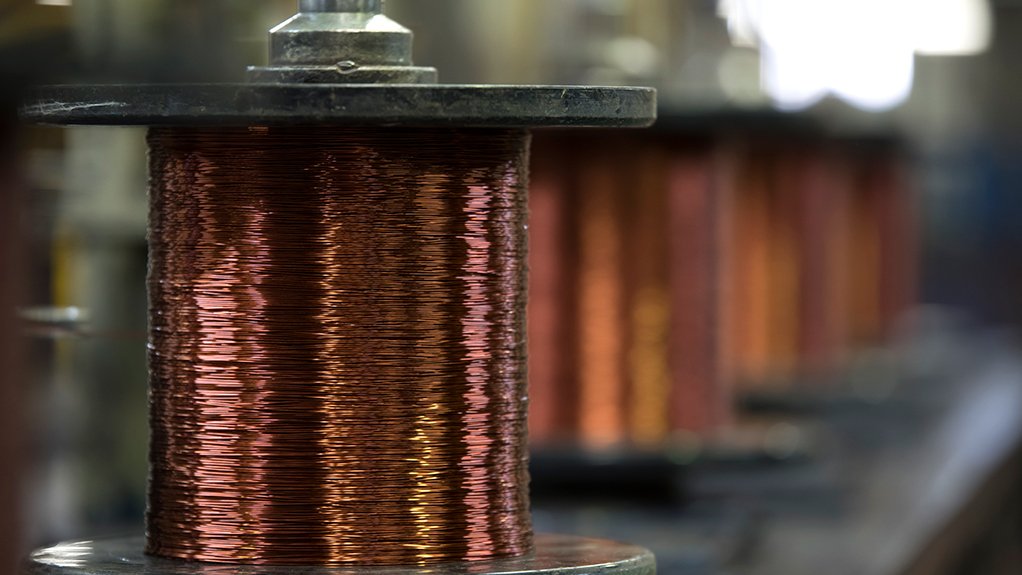

Wilec products conductors of green energy transition

With power generation and electric vehicles (EVs) presenting the greatest demand for Gauteng-based manufacturer Wilec’s oxygen-free copper rod, and enamelled and covered conductors, the company is positioned to play a significant role in Africa’s green energy transition.

“Wilec has produced oxygen-free copper rod, and enamelled and covered conductors under its Transwire brand since 1975. Today, the brand has evolved into the largest manufacturer of enamelled magnet wire, rectangular and shaped conductor products in South Africa,” says Wilec CEO Nene Mathebula.

The company supports various industries through its manufacturing and supply of high-quality, oxygen-free copper rod, and enamelled and covered conductors, which are exported throughout Africa, mainly for automotive, electric motor and transformer manufacturing and repair.

“Copper rod, and enamelled and covered conductors have a range of uses, including those that are paramount for the green energy transition,” emphasises Mathebula.

Climate change and the subsequent need to reduce global carbon emissions has compelled the automotive and power generation industries to investigate innovative ways to meet the world’s everyday needs in a more sustainable manner.

“Renewable energy solutions and EVs are at the helm of the green energy transition, and copper products will play an important role,” says Mathebula, adding that the company is expanding its presence and establishing a footprint in East Africa.

He adds that the call for sustainability is one that is deeply embedded in Wilec’s business model and, as such, the company believes its copper products must reflect this.

Wilec’s migration to a more sustainable manufacturing operation has involved an intensive modernisation and recapitalisation programme, which has been rolled out at its Olifantsfontein and City Deep facilities in Johannesburg.

The installation of “state-of-the-art machines” has improved quality, control and efficiencies, and product diversification and market substitution were also considered during procurement and planning when buying equipment.

This is in addition to training Wilec’s manufacturing teams so that “man and machine are equipped to deliver products that exceed specification and customer demands”, says Mathebula.

The oxygen-free copper rod, and enamelled and covered conductors are manufactured to order, according to industry specifications and customer needs, as these may differ depending on the customer’s end use.

During manufacturing, a sophisticated upcast rod casting process, using high purity grade copper, is employed along with the most innovative mechanical testing methods.

“The copper rod production process entails a vertical upward casting configuration through a water-cooled graphite die that complies with industry standard diameters. The rod is then coiled, palletised and packaged to facilitate ease of use and handling. Typical coil masses range between 3 t and 4 t,” explains Mathebula.

Most of the raw materials used in the production of Wilec’s oxygen-free copper rod, and enamelled and covered conductors are sourced locally and are benchmarked against international standards. The company is committed to participating in local sourcing opportunities and aims to increase local content where possible.

“The Covid-19 pandemic, as well as the supply chain constraints faced, owing to global factors, remain a challenge for many businesses. This has posed some challenges in sourcing some of our raw materials; however, we have adequate measures in place to ensure that our production process is not affected,” says Mathebula.

More than 500 people are employed at Wilec’s Johannesburg, Durban and Cape Town branches, where its products are manufactured and sold.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation