Steel key to circular economy

GREEN IMPERATIVES The Hot Dip Galvanizers Association of South Africa highlights the importance of galvanised steel in promoting green consciousness

Not-for-profit trade organisation, the Hot Dip Galvanizers Association of South Africa (HDGASA) implores its members to embrace the important role that steel can play in promoting a circular economy.

HDGASA executive director Robin Clarke asserts that it is time for the steel sector to move away from linear business models where products are manufactured from raw materials and discarded at the end of their perceived usefulness.

Author Bruno Dursin, who wrote the article titled ‘A bright future for hot dip galvanised steel in the circular economy’ points out that the steel industry is already contributing towards the circular economy by actively promoting and developing the use of high-strength and advanced high-strength steel grades.

Clarke highlights that hot dip galvanising contributes by further extending the service life of steel. He also suggests that buildings be specifically designed for reuse, to the point where the same building can even be relocated.

“When you demolish a traditional building, you end up with a lot of rubble that cannot be repurposed. If you had a building largely constructed from steel, you would be able to reconfigure it differently – or design a building using elements [that] can be reused with minimal rework,” he notes.

He cites, as an example, the Green House in Utrecht, in the Netherlands, which was built as a contemporary structure on land identified for reuse.

Its two-layer pavilion was designed as a generic-construction steel frame comprised of hot dip galvanised profiles, which can be disassembled and rebuilt at another site. He notes that the design’s ability to be relocated to another location is facilitated by a modular construction system.

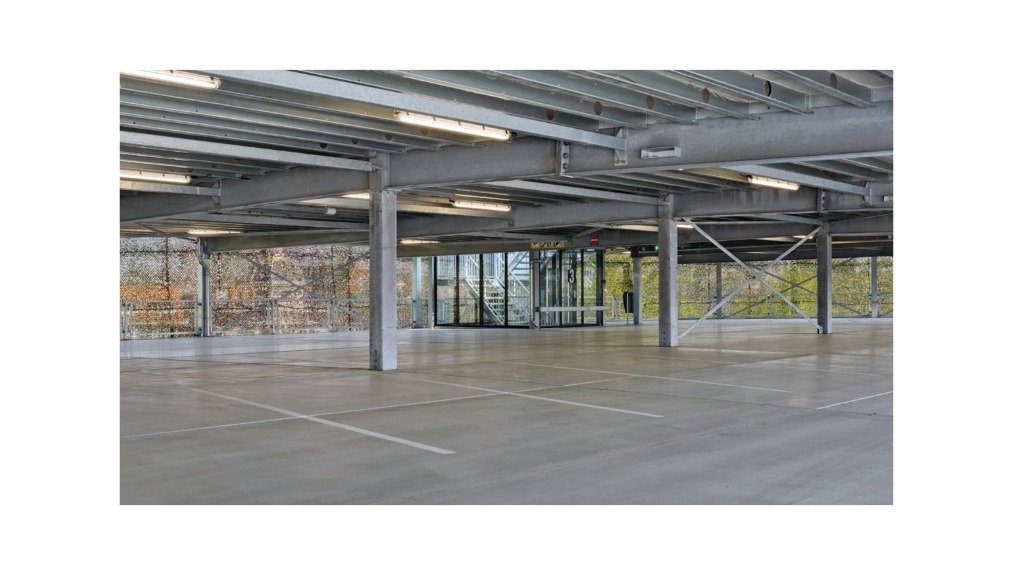

Another example is that of a temporary parking garage in Leiden, also in the Netherlands. This 410 m2 parking garage can be disassembled and all steel elements, including columns, beams, cross-members, cladding and fencing, are designed for minimum maintenance and, ultimately, repurposing after a decade.

Meanwhile, Clark points out that zinc, which is integral to the hot dip galvanising process, can be recycled continuously without any loss in quality, differing from many other synthetic materials, where recycling degrades quality.

In South Africa, zinc ash and zinc dross, as by-products of the hot dip galvanising process, are regarded as hazardous waste despite the fact that they can be recycled back to pure zinc or into oxides that can be used to make tyres, fertiliser, sun block and burn treatments.

The HDGASA states that it assisted with an application to remove zinc-related wastes from the hazardous waste register two years ago and is still awaiting an outcome. Other changes are gaining traction including the conversion to ‘greener’ natural gas, with about half of the country’s galvanisers following this route.

Overall, South Africa’s hot dip galvanising sector is now more efficient in controlling emissions, and “ensuring that all chemicals, chemical elements and molten metals are managed in accordance with best practice”, Clarke concludes.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation