Booyco expands PDS footprint to Namibian mine

The Booyco CXS allows end users to achieve Level 9 compliance.

Booyco Electronics proximity detection solution will enhance safety during the development phase of Wolfshag.

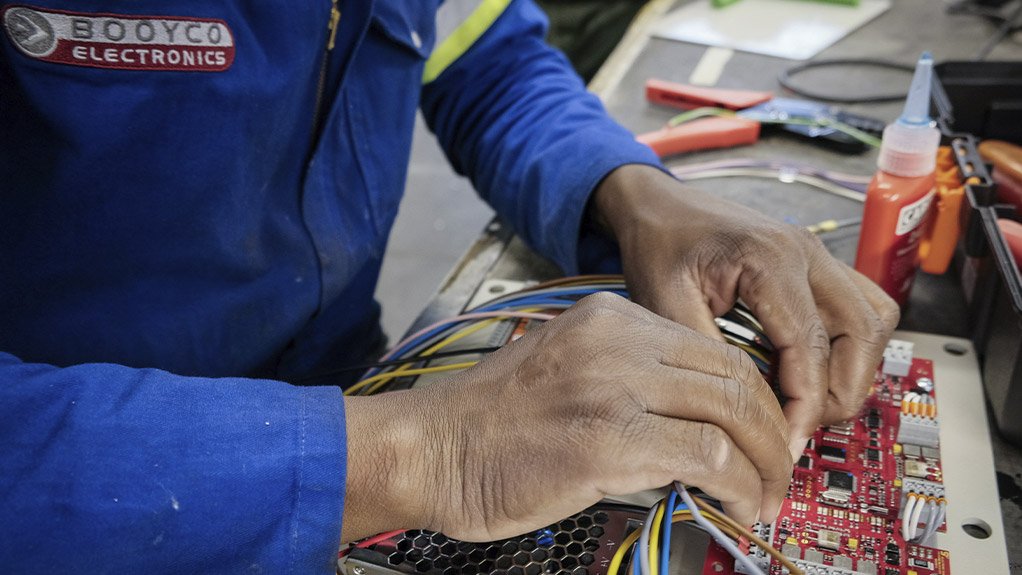

Booyco Electronics is at the forefront of fit-for-purpose proximity detection technology.

This article has been supplied.

Proximity detection leader Booyco Electronics is equipping 19 mechanised mining machines with its latest Booyco CXS proximity detection solution to enhance safety during the development phase of underground operations at Namibia’s largest gold mine.

According to Anton Lourens, Booyco Electronics CEO, the order was placed by long-time customer Murray & Roberts Cementation, who will be establishing the underground stoping horizon for the Wolfshag zone of B2Gold’s Otjikoto mine.

The contract also includes sensing devices for 120 underground personnel on the operation, which will be located in the employee’s cap lamp to provide an alarm.

“Our equipment will help achieve the highest level of safety by mitigating the risk of collisions between pedestrians and vehicles, and between vehicles, on this project,” says Lourens. “The installation of our CXS units is in line with the commitment by the mine and the contractor to zero harm in the workplace.”

The Cementation Lewcor JV contract will take 28 months. Lewcor Mining is a Namibian company with extensive mining experience in that country. The contract includes a decline of 5.0 m wide by 5.5 m high being driven to the orebody from a portal in one of Otjikoto’s depleted open pits. The operation will be highly mechanised, with equipment including drill rigs, dump trucks, load-haul dumpers and utility vehicles, as well as shotcreting and ancillary equipment.

Lourens highlights that Booyco Electronics’ latest generation CXS system being used on the project is a comprehensive and integrated proximity detection solution. The technology takes a step beyond being just a warning system to becoming a true collision avoidance system.

“The CXS system on this project will deliver Level 7 and Level 8 capability in terms of the Earth Moving Equipment Safety Roundtable (EMESRT), and can also accommodate Level 9,” he says. “Although there is not yet a legal requirement for collision avoidance systems in Namibia, our customer and the mine adopt a global best practice approach to all aspects of safety in mining operations.”

With the mine’s location more than 300 km north of Windhoek, it was important that the equipment is robust and reliable to ensure maximum uptime, he says.

“To ensure that the equipment performs optimally, we have trained the customers’ artisans on how to look after it,” Lourens says. “A qualified serviceman from Booyco Electronics will also visit the site regularly to audit performance, assess the equipment and conduct any necessary maintenance.”

A pioneer of proximity detection systems in South Africa, Booyco Electronics’ home-grown technology has seen wide take-up in underground operations – both hard rock and coal – as well as in the opencast environment, plants and warehouses.

“Since our inception in 2006, safety regulations have changed significantly,” he says. “An important strength of our technology is that it has constantly evolved to meet the needs of the industry.”

The company now has a footprint of over 100 mining customers in South Africa, and this Namibian project is part of its gradual expansion into other countries in Southern Africa. He highlights that collision avoidance systems are likely to become increasingly mandatory in neighbouring states as these countries usually follow South African regulations. Major miners are also driving change through the globally recognised EMESRT guidelines.

“The International Council on Mining and Metals is also an important stakeholder in this process,” Lourens says. “The ICMM highlights that transport and mobile equipment accidents were highest cause of fatalities at their members’ operations in 2018, accounting for 30% of fatalities.”

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation