Coating tech protects critical equipment

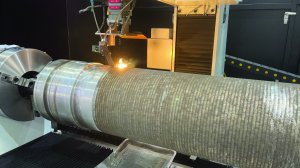

EMBEDDED RESILIENCE Laser cladding involves applying a coating material onto a substrate using a high-powered laser to melt the coating material and a thin layer of the substrate, creating a metallurgical bond

Laser-applied cladding technology provides robust and long-lasting coatings that enhance the performance and lifespan of critical components required for hydraulics, pneumatics and hydropower environments, reports specialised welding and thermal spray products supplier Weartech CEO Simon Wintle.

These industries face significant challenges from wear, corrosion and erosion as a result of high-pressure operations and harsh conditions.

Laser cladding involves applying a coating material onto a substrate using a high-powered laser to melt the coating material and a thin layer of the substrate, creating a metallurgical bond.

“This process enables precise control over the coating thickness and composition, resulting in high-quality, wear-resistant surfaces,” he tells Mining Weekly.

Common materials used in laser cladding include nickel, cobalt and iron-based alloys, as well as carbides and ceramics.

Hydraulic systems – such as cylinders, pistons and valves – operate under high pressure and continuous movement, leading to wear and tear.

“Laser cladding provides coatings that significantly enhance wear resistance and reduce friction, extending the lifespan of hydraulic components and improving system efficiency and reliability. These coatings also offer superior corrosion resistance, essential for hydraulic systems exposed to various fluids and harsh conditions,” highlights Wintle.

Pneumatic systems, which use compressed air to transmit power, benefit significantly from laser cladding solutions as their components – such as air cylinders, actuators and rotary joints – are prone to wear and corrosion as a result of exposure to moisture and particulates.

“Laser cladding provides a durable protective layer that enhances resistance to wear and corrosion, resulting in lower energy consumption and extended maintenance intervals, ultimately enhancing product- ivity and reliability,” he points out.

In the hydropower industry, Wintle notes that components such as turbines, gates and other critical items are continuously exposed to high-velocity water flow, causing erosion and cavitation. Here, he says, laser cladding offers a robust defence against these issues by apply- ing erosion-resistant coatings that protect surfaces from abrasive action.

“This extends equipment lifespan and enhances efficiency by maintaining smooth surfaces, reducing drag and improving water flow through turbines, resulting in better energy conversion and increased power output,” notes Wintle.

Real-World Applications, Future Innovations

Wintle tells Mining Weekly that case studies highlight the effectiveness of laser cladding solutions. For example, he says a hydropower plant managed to reduce maintenance costs and downtime by applying laser cladding to turbine blades.

Similarly, a hydraulic equipment manufacturer improved wear resistance and operational efficiency with laser-clad components.

“The future of laser cladding solutions is promising, with ongoing research focused on creating even more advanced coatings. Innovations such as tailored composite materials and improved laser technologies are expected to enhance the performance and sustainability of laser cladding applications,” states Wintle.

By offering “superior” protection against wear, corrosion and erosion, he says laser coatings enhance the durability and efficiency of critical equipment, leading to reduced downtime, lower maintenance costs and improved overall performance.

“As technology continues to advance, the role of laser cladding in these industries will undoubtedly become even more significant, driving innovation and sustainability for years to come,” concludes Wintle.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation