Company Announcement: Corobrik Specified for Mine Housing in the Northern Cape

This article has been supplied.

South Africa has the largest known deposits of manganese ore in the world and is the largest producer of iron ore on the continent making mining operations in the arid Northern Cape critical to the national economy and the largest employers in the region. Production volumes amongst the two biggest players in the region’s mining sector - Assmang and Anglo American – continue to increase at a tremendous speed. To both cater for new employees and respond within the ambit of the revised mining charter published by government in late 2010, both mining giants are in the throes of creating new and upgrading existing accommodation with a number of housing projects both on the drawing board and under construction.

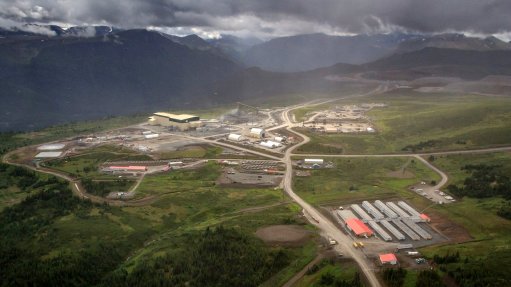

Gary Westwood, Sales Manager for the Free State and Northern Cape region said that Corobrik took pride in being a part of the progress of a sector that was the greatest contributor to the country’s gross domestic product. For example, Anglo American’s Kumba Iron Ore operation, which is located in Sishen near the town of Kathu, is believed to be one of the seven largest open pit mines in the world. It produced 38,9 Mtpa in 2011. “Kumba is currently building 60 mine management houses with our Blue Barley Travertine and Roan Travertine face bricks. A contract for the construction of a further 479 50m2 houses has been awarded to Steffanuti Stocks and is scheduled to begin before year end,” he said.

In addition, production at the new Kolomela mine in Posmasburg came on stream in May this year (2012) and is expected to add additional production of 13Mtpa. “This Kolomela mine expansion saw Corobrik delivering some two million Corngold Satins for the building of 400 staff houses. This project has been divided into three projects, namely Postdene, Airfield and Boichoko,” he added. Quoting the revised Mining Charter of 2010, Gary Westwood pointed out that during the apartheid era, the mining sector was known for the appalling living conditions under which its workers lived, which led to a myriad of social ills including the destruction of the social fabric of communities, substance abuse, as well as the contraction and spread of diseases.

“Review in 2009, prior to the amendment of the charter, indicated that many mines were making solid efforts to upgrade housing with many moving away from controversial hostel systems to create quality family homes. To build on this, new policy guidelines have since been put in place to ensure that accommodation was not only consistent with international best practices but also to help facilitate home ownership for all mine employees by 2014. It is a stipulation that home ownership must be both affordable and sustainable,” he said.

He said that, in meeting the objectives of the mining charter, the use of clay brick in housing projects went a long way to provide both affordable and sustainable housing. Very importantly, a clay brick house meets the aspirational requirements of the prospective homeowners to live in ‘proper’ houses and all the dignity associated with that. Miners keen to be housed may consider themselves fortunate that South Africa has not compromised and digressed from its well-entrenched masonry tradition and all the associated benefits that clay brick brings to house construction.

“Brick fits all three dimensions of sustainability. At a social level nobody wants the stigma attached to living in a prefabricated box and there is no good reason that they should. Clay brick construction is proven economical as built and its record of performance, its robustness, its durability assures a low lifecycle cost. Add to that, that clay bricks have mineral properties that meet all necessary requirements for

Healthy living, that clay bricks release no toxic fumes under both normal and fire conditions to impinge on air quality, that they have natural sound insulation properties to support quiet indoor environments and clay bricks sustainable value emerges in a unique holistic context.” He added that, in light of the fact that the region bordered the Kalahari desert and had some of the most acute temperature fluctuations in the country, the energy efficiency that resulted from the use of clay brick was particularly important. The real benefits of clay brick construction are to be realised in our long hot summer months when the natural thermal properties of clay brick help attenuate the impact of high outdoor temperatures indoors.

“The value of thermal mass the clay brick walls provide, slows the heat flow to the inside by 6 to 8 hours over the hottest parts of the day, moderating internal conditions and providing target thermal comfort for longer, reducing artificial cooling interventions. Miners won’t have the problem of overheating inside so widely associated with insulated lightweight walled Alternate Building Technologies such as Light Steel Frame Building. The use of clay brick in this instance well complements the priority being given to the use of solar power in these projects” he added.

Gary Westwood said that one of the most critical housing projects in the Northern Cape – and one of the greatest challenges faced by the mining industry as a whole – was the resettlement of residents to facilitate the expansion of a mine. “Plans are currently being finalised to relocate the entire town of Dingleton situated 12 kilometres south west of Kathu to allow further expansion at the Sishen mine. This will require the building of more than 500 houses as well as schools, police stations and commercial properties.”

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation