Delba Electricals’ expertise in repairing low voltage motors up to 1 000 V

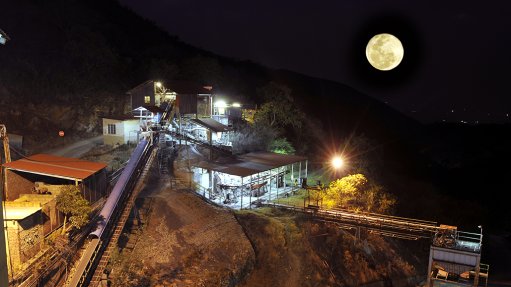

Rotating equipment repairer Delba Electrical has long been a leading name in the world of electric rotating machines. Renowned for its dedication to quality, innovation and reliability, Delba has built a strong reputation in the market. Part of what makes it an industry leader is its state-of-the-art low voltage motor repair facility. Let’s take a closer look at the facility, its capabilities and why it stands out in the world of electric motor repair.

When it comes to the repair and maintenance of low voltage

motors up to 1 000 V, Delba Electrical stands out as a leading expert in the field. With a state-of-the-art facility and a team of skilled employees, Delba Electrical offers a wide range of services to ensure the reliability and efficiency of various motor types.

Workshop Layout

Delba Electricals’ repair facility is equipped with a well-organised shop layout that comprises a mechanical and electrical section. The mechanical shop is equipped with cutting-edge tools and the equipment necessary for disassembling, accessing and repairing electrical rotating machines. The electrical shop, on the other hand, is dedicated to handle electrical aspects, including rewinding, testing and troubleshooting on stators and rotors of electrical motors.

Crane Capacity

Efficient handling of heavy equipment is crucial in motor repairs. Delba Electrical boasts a robust crane capacity of 12.5 t plus 10 t (2 x 5-t) SWF hoist gantries with long and cross travel (complete floor coverage) in the mechanical workshop, and 10 t plus 3.2 t SWF hoist gantries with long and cross travel (complete floor coverage) in the low voltage electrical workshop. It can manage even the largest low voltage motors ensuring safe and effective manoeuvring during the repair process.

Burnout Oven

Delba Electricals’ burnout oven plays a pivotal role in motor repair. This specialised oven is used to remove old insulation and varnish from windings. It ensures a clean and prepared surface for rewinding, ultimately contributing to the motor’s improved performance. The burn-off oven is a pyrolytic kiln gas-fired oven with PLC control and water quenching system. It also consists of temperature chart recorders and comes in at 3 m wide x 3 m high x 4 m deep.

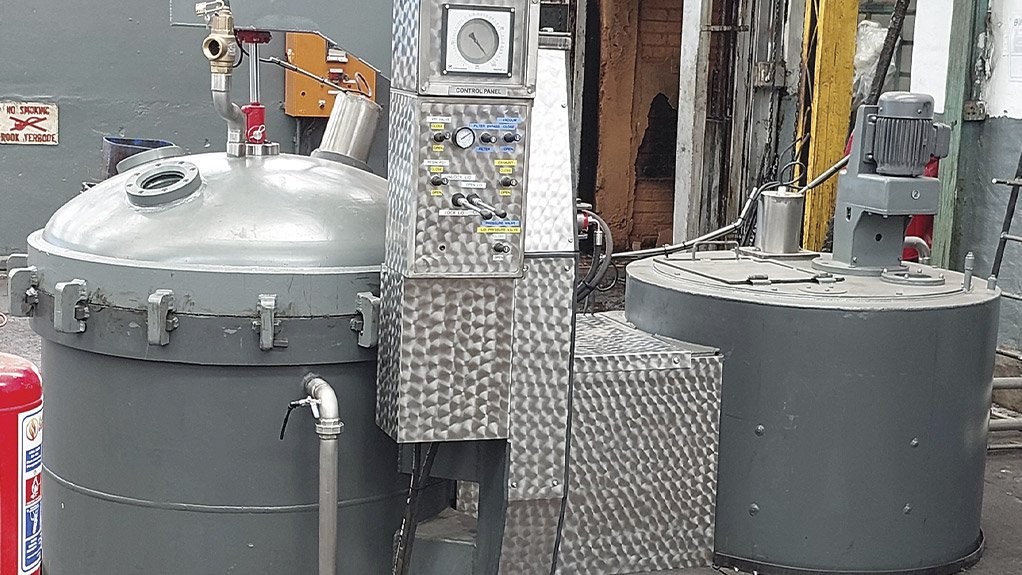

Vacuum Pressure Impregnation (VPI) Tank

VPI is a critical step in motor repair. Delba Electricals’ VPI tank is designed to impregnate windings with a special varnish under vacuum and pressure. This process enhances the insulation, protecting the motor against environmental factors and extending its lifespan.

Curing Oven

After rewinding and impregnation, the motor windings must be cured to achieve optimal insulation properties. Delba Electricals’ curing oven is precisely controlled to ensure the winding insulation is properly set, providing reliability and durability. The baking and curing ovens consist of a gas fired oven with digital control and temperature chart recorder. (1.4 m wide x 2.6 m high x 5.5 m deep)

Spray Booth

The spray booth is an essential component of the finishing process. Delba Electricals’ spray booth is used for applying protective coatings and paints, safeguarding the motor against corrosion and wear.

Balancing Machine

Balancing is crucial to ensuring the smooth and vibration-free operation of low voltage motors. Delba Electricals’ balancing machine is capable of precisely balancing rotors, reducing stress on bearings and increasing the motor’s overall efficiency.

Testbay Facility

A comprehensive testing facility is integral to Delba Electricals’ repair capabilities. They employ advanced testing equipment to evaluate motor performance, efficiency and adherence to specifications. This ensures that repaired motors are in optimal working condition.

The Importance of Low Voltage Motors

Low voltage motors are the lifeblood of many industries, powering machinery and equipment essential for production, manufacturing and more. Motors ranging from small to medium-sized are the workhorses behind various processes. When a motor fails, it can lead to costly downtime and disruptions, making quick and efficient repairs crucial.

Wide Range of Low Voltage Machines

Delba Electrical caters to a broad spectrum of low voltage rotating machines, including:

- AC Motors: Delba Electricals’ expertise extends to a wide range of alternating current (AC) motors, from small fractional horsepower units to large industrial AC motors.

- Slip Ring Motors: Slip ring motors, often found in heavy industrial applications, are skilfully repaired by Delba Electricals’ technicians, ensuring that they perform reliably and efficiently.

- Vibrator Motors: Vibrator motors are commonly used in applications such as vibratory feeders and screens. Delba Electrical specialises in repairing and maintaining these motors, critical for consistent operation.

- Pumps: Pumps are integral in many industrial processes, and Delba Electricals’ repair services cover various types of low voltage pumps, ensuring their reliability and performance.

- Fans: Fans are used for ventilation, cooling and various other applications. Delba Electrical offers comprehensive repair solutions for low voltage fans to maintain their functionality.

Delba Electricals’ capabilities in repairing low voltage motors up to 1 000 V are second to none. Its well-structured shop layout, advanced equipment and skilled workforce ensure that motors are restored to peak performance. Moreover, its expertise spans a wide variety of low voltage rotating machines, making it a preferred partner for businesses in need of reliable motor repair services. When it comes to the longevity and efficiency of low voltage motors, Delba Electrical is a name you can trust.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation