Driving Productivity In The Iron Ore Sector

This article has been supplied.

Government’s New Growth Path sets a target of six million new jobs by 2020 and identifies six key sectors that must drive growth and job-creation. A particular focus is to ensure greater local processing of South Africa’s abundant natural resources. This policy framework prioritises the mining value chain, which includes mineral beneficiation, as one of the key economic activities that present the highest value proposition towards the attainment of its objectives.

The South African iron ore mining sector is globally competitive and produced 67 million metric tons in 2013.It is believed that the iron ore industry can more than double output in the next ten years, creating 14 000 new jobs and uplifting areas such as Limpopo and the Northern Cape. MBE Minerals can provide the necessary capital equipment for the iron ore beneficiation processes and is able to access over 150 years of experience gained in the tough and demanding global mining industry, with more than 40 of those in Africa, to determine best fit solutions.

BATAC® jigs

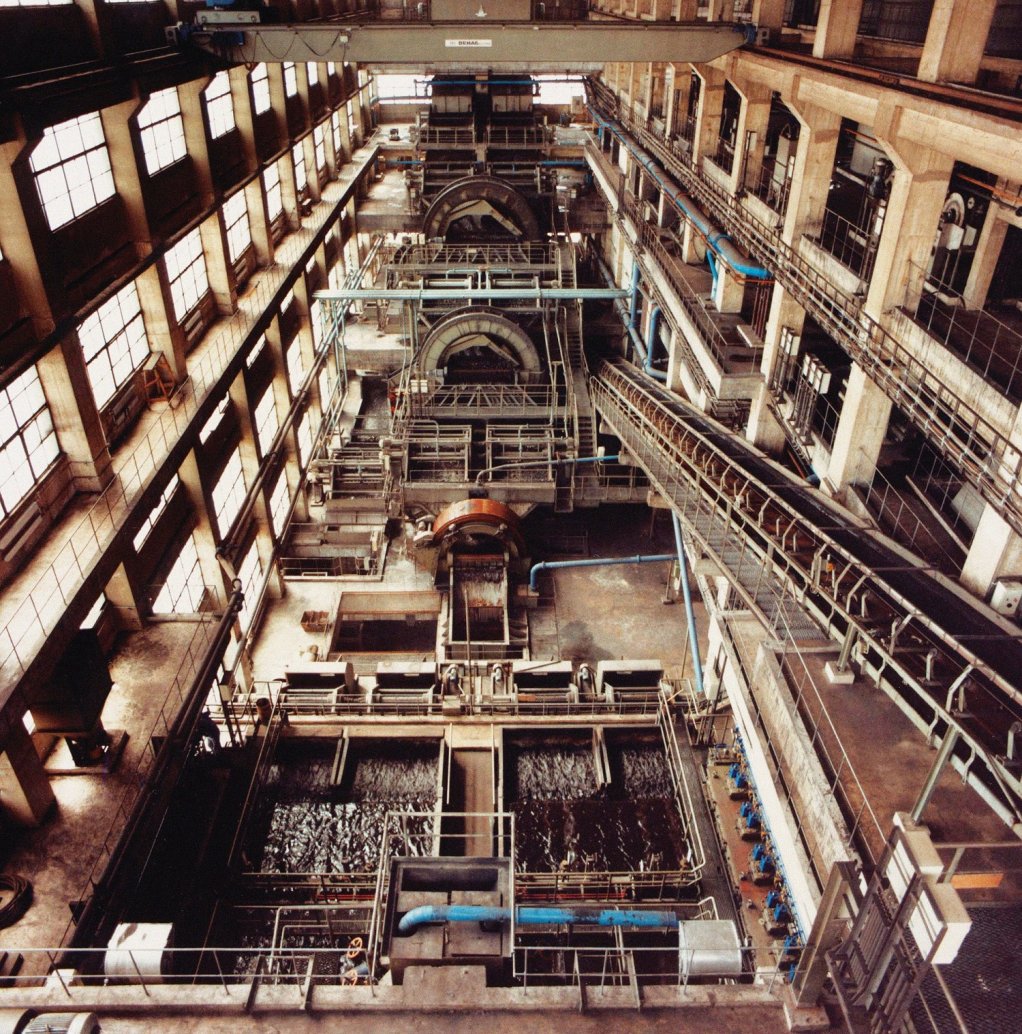

The quality requirements laid down by the mineral industry for raw materials to ensure efficient furnace operation are becoming increasingly more stringent. The rapid detection of changes in the raw material, quick reaction to such changes and easy operation of BATAC® jigs is gaining ground for the technology in the iron ore beneficiation sector.

The iron ore industry is increasingly recognising the high efficiencies, significant economic benefits, improved product quality and machine availability, as well as the higher throughput rates that are achievable with MBE Minerals’ BATAC® jigs. “Stratification by means of jigging is one of the oldest separation methods in the history of mineral and coal beneficiation,” Johannes Kottman, managing director of MBE Minerals comments. “In the early days of beneficiation, separation was achieved either by moving the entire jigging bed screen (side pulsed BAUM jig), limited in operating width to two metres and hence throughput capacity, or through water pulsation generated in an air chamber beside the jigging bed. In the 1960s, to overcome the counter-productive limitations of these historical technologies, MBE introduced the underbed pulsed high throughput capacity Batac® jigging technology to the market.

“BATAC® jig technology has excellent separation accuracy, is relatively small in footprint and has a comparatively low capital cost,” Kottman says. “Every benefit the technology offers has been field-proven through extensive and diverse test work.” BATAC jigs not only excel in their high separation efficiencies, but also in terms of ease of operation, robust design and minimised maintenance costs, making them the preferred technology for numerous beneficiation plants worldwide.

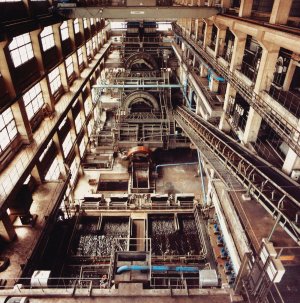

Jones® WHIMS

MBE’s robust Jones® Wet High Intensity Magnetic Separator is characterised by a high throughput capability, coupled with simple maintenance and lower energy consumption. The compact Jones® unit allows installation in small buildings and is ideally suited to treating feebly magnetic minerals with a particle range from 20 µm up to 1 mm. “The Jones® WHIMS can operate at up to 13 000 Gaus and due to the special design of the grooved plates, the gaps keep their dimension for a longer operational time, generating a uniform magnetic force, which is essential for selective separation,” says Kottmann.

PERMOS MIMS

PERMOS MIMS is a cost effective medium-intensity magnetic drum separator which allows wet and dry separation of high grade coarse and fine ferromagnetic and paramagnetic ores with a medium susceptibility, at high throughput rates, with minimal energy consumption. The PERMOS operates at field intensities of 5.000 Gauss on the drum surface.

Pneuflot®

MBE Minerals’ Pneuflot® technology exhibits a number of advantages over conventional technology. “The flotation cell improves product quality, recovery and efficiencies, as well as delivering lower capex and opex, and significantly lowering wear costs. The implementation of Pneuflot® has also resulted in substantial savings in energy consumption, space and manpower requirements,” says Kottmann. Available in sizes ranging in diameter from 800 mm to 6 m, the Pneuflot® systems have been successfully installed in a number of industrial applications. Slurry feed rates of 10 to 1 400 m3/h can be achieved in a single cell, depending on cell diameter.

Screens

The company’s vibrating screens have a well-established track record in the African mining industry, with products available for sizing, scalping, dewatering and media recovery. The screens feature an innovative side plate mounted drive, making them lighter than those utilising vibrator motors.

The company also supplies screens with vibrator motors where required, while its resonance screens offer the benefit of low power consumption. Sound mechanical design elements include vibration damping, side plates, cross members and the appropriate feed and discharge chutes. All types of screening surfaces can be accommodated.

Feeders

The company’s range of vibrating feeders, designed in Germany and manufactured locally, feature feed capacities of 100 up to 3 000 tph and are suitable for all applications where controllable discharge of bulk materials is required. Replaceable bolt-on wear liners are fitted to the feeder troughs to prolong feeder life.

Feedback from customers is critical to the successful development of sustainable, industry-centric products. This information is shared with the company’s global partners and principals and MBE Minerals receives expertise and technical support from its worldwide network, including the MBE Coal and Minerals Technology’s R&D centre in Cologne, Germany.

“The R&D centre consults with customers from all parts of the world with regard to optimum processing and this service is backed up by an in-house laboratory facility and pilot test work capabilities. The centre is also used as a training facility for customers, either on general mineral processing or on the operation and maintenance of specific MBE equipment,” Kottmann concludes.

PRODUCT OFFERING FOR IRON ORE PIC 01 : Teska technology is gaining increasing recognition for delivering higher efficiencies, huge economic benefits, better product quality, better machine availability and higher throughput rates than other technologies.

PRODUCT OFFERING FOR IRON ORE PIC 02 : MBE’s robust Jones® Wet High Intensity Magnetic Separator (WHIMS) offers a high throughput capability.

PRODUCT OFFERING FOR IRON ORE PIC 03 : MBE’s Pneuflot® technology is widely hailed as a flotation technology of the future, surpassing the popularity of conventional technology.

PRODUCT OFFERING FOR IRON ORE PIC 04 : BATAC® jig technology has excellent separation accuracy, is relatively small in footprint and has a comparatively low capital cost.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation