Dry-running hydrogen compressors’ performance overhauled

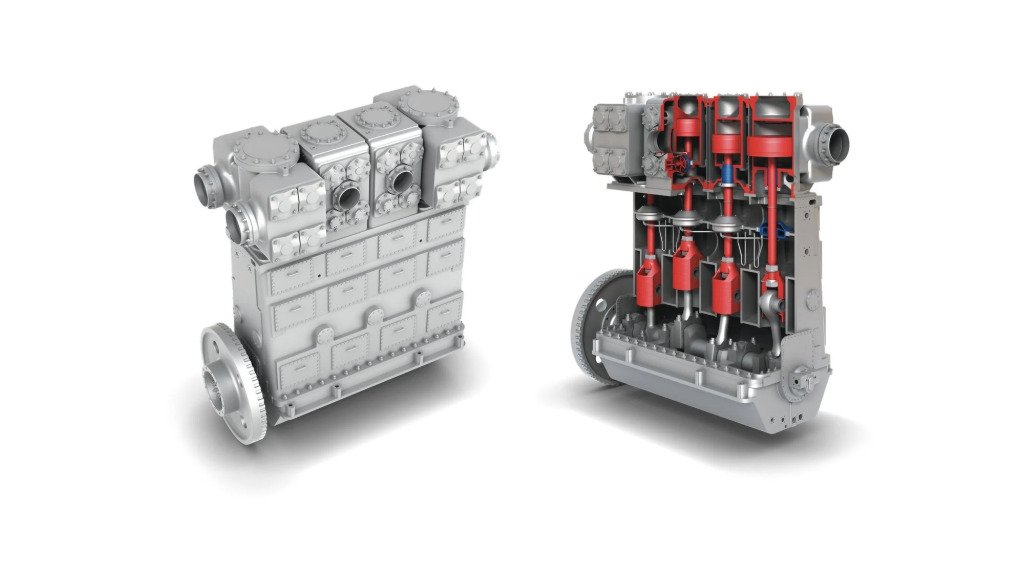

STRONG MARKET POSITION Burckhardt Compression high-pressure compressors are valued for their role in various industries that require high-pressure gas compression, especially in energy and chemical processes

INNOVATION AND SUSTAINABILITY Being actively involved in developing solutions for the energy transition, including compressors for green hydrogen and ammonia is an effective way of demonstrating a commitment to sustainable technologies

A plant in South Africa, which was losing up to 20% of output owing to frequent downtime over more than ten years, experienced a turnaround in performance owing to a range of solutions from global reciprocating compressor solutions firm Burckhardt Compression.

The firm points out that it is always best to operate a business with minimal maintenance costs, while achieving efficiency and reliability targets. However, industries such as gas compression present many challenges and keeping key equipment, such as reciprocating compressors, in prime condition requires considerable expertise.

Burckhardt Compression notes that sealing dry-running hydrogen compressors is particularly challenging as maintaining effective seals to prevent the escape of the “smallest molecules in existence” is a complex task.

For the client, Air Products South Africa, the two non-Burckhardt Compression dry-running hydrogen compressors were a cause for very high maintenance costs and wearing parts were being replaced every month. This not only increased costs and downtime, but the leakages equated to lost revenue too.

Air Products South Africa called in Burckhardt Compression to establish the source of the problems and to propose long-term engineering solutions. The initial investigation showed that the sealing elements and the piston rods were at the heart of the problem. Internal leakages were causing reduced gas flow as well as temperature issues and a significant loss of efficiency.

The root cause analysis identified several areas for improvement, including a redesign of second-stage packing case assemblies and a piston rod refurbishment. The project would also involve the creation of a new piston ring set and the upgrading of materials to the latest design, along with the renewal of the cylinder liners.

The Repair Strategy

The execution of the refurbishment project was carefully planned to optimise delivery and minimise downtime. New parts were manufactured and delivered to site to enable one compressor to be overhauled while the second remained in service. Once complete, the renewed compressor was recommissioned and work began on the second unit, while performance data on the first machine was monitored closely.

“The results were pleasing on several levels.”

The compressors ran for 22 months without incident – “the monthly replacement of parts is a distant memory”, says Burckhardt Compression. Meanwhile, internal leakage was stopped – a considerable achievement on a hydrogen compressor – and emissions were significantly reduced along with maintenance costs.

Equally important, production losses, which had been established at 20%, dropped to just 2%. At the same time, the wearing parts designed and installed by Burckhardt Compression delivered a substantial increase in service lifetime and the energy consumption by volume of produced gas was reduced by 25%. The operator was surprised by the scale of the improvements.

“We didn’t think that this level of performance was possible,” Air Products South Africa senior mechanical field engineer Johan Maartens told Burckhardt Compression.

“[The company] diagnosed the issue swiftly and executed the repairs with precision. Our second compressor was booked in for the same refurbishment and we will be involving Burckhardt Compression in many more overhaul projects in other facilities, based on the remarkable results of this project.”

Where some operators may have considered the compressors beyond redemption, Air Products saw an opportunity to retain the existing equipment with improvements that would extend their service life and sustainability. The result was a significant short- and long-term cost saving for the business, as well as greater peace of mind regarding some of its most crucial machinery.

Customer-Centric Offering

Meanwhile, an influx of new, major projects within the North American market has been attributed to Burckhardt Compression’s customer-centric approach.

By leveraging local engineering expertise with a global presence and a history dating back to the 1840s, the company is uniquely positioned to meet the diverse and evolving needs of its customers across this and other regions.

Burckhardt Compression US MD Annie Savarimuthu notes that, “North America is an incredibly vibrant and diverse market; the needs of an operator working in the Caribbean will be very different to those of one based in Canada, for example.”

She notes that the company’s recent successes across the continent demonstrate its “deep commitment” to its customers.

An example of this customer-centric approach is its recent success with a renowned power generation company in Canada. In early 2025, Burckhardt Compression secured a significant order for two process gas compressors to support hydrogen recovery at the customer’s tritium removal facility.

The project directly supports the customer’s commitment to cleaner energy solutions and a more sustainable operational footprint and reflects both “strong regional collaboration and trusted long-term customer relationships”.

“This major win brought together expertise from across the Americas and beyond, with coordinated support from project management, legal, logistics, finance, sales and service teams,” says Savarimuthu.

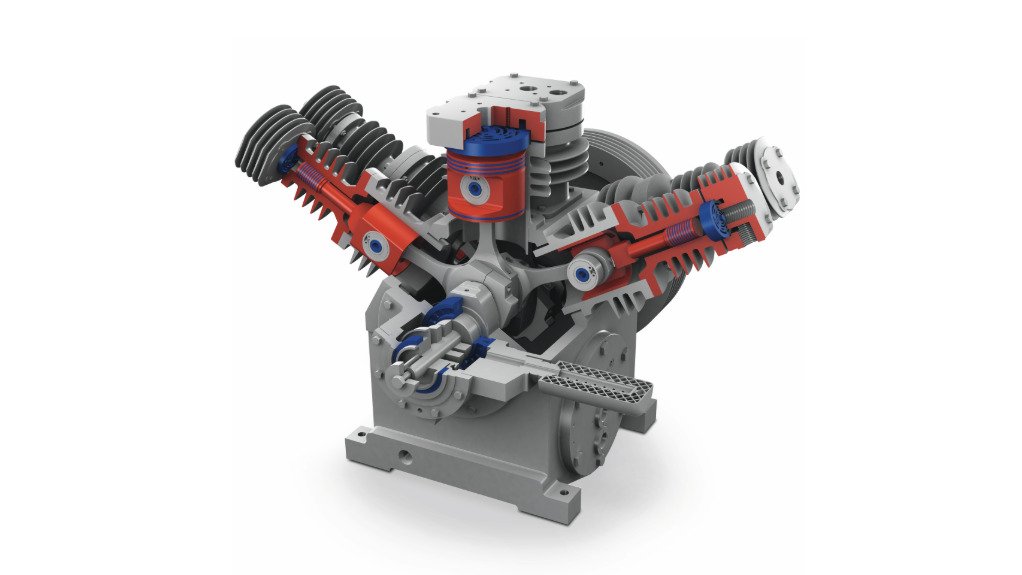

Another example of agility and customer focus came when Burckhardt Compression provided a “cost-effective, quick-delivery, high-speed reciprocating compressor packaged solution” for a global leader in cryogenic gas processing equipment.

The customer needed a reliable, turnkey compressor solution for a liquefied natural gas terminal project in Nicaragua, with a tight six-month deadline. Burckhardt Compression delivered the solution on time and established a strong partnership that has since led to further orders.

“These projects show what’s possible when we combine local insights with the resources of a global organisation,” Savarimuthu adds.

“We’re one of a handful of fully vertically integrated compressor companies in the world. That means we can control quality at every level – from casting to commissioning. [We] leverage our new systems, aftermarket services, digital product offerings and continue to deliver safe, reliable, sustainable and high-performance systems,” she concludes.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation