Enhancing filtration efficiency in zinc electrolysis

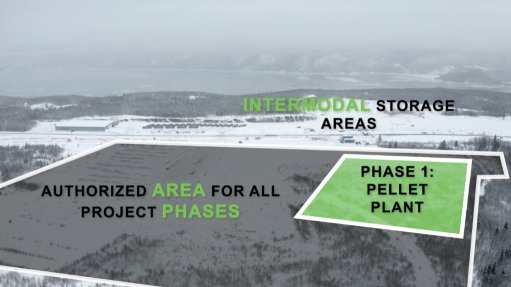

At its site in Hobart, international zinc producer Nyrstar has implemented a technical upgrade as part of a broader capacity expansion. A new membrane filter press was installed to optimise solid-liquid separation within the roast-leach-electrowinning (RLE) process. The objective: improved process consistency, enhanced metal recovery, and a safer working environment.

Filtration as a Critical Step in the RLE Process

The RLE process, a widely used method in zinc production, involves the roasting of zinc concentrate and subsequent leaching of the calcine in sulfuric acid. This yields a zinc-containing slurry that must be reliably separated from solid residues. Inadequate filtration at this stage can lead to metal losses, process disruptions, and increased downstream workload.

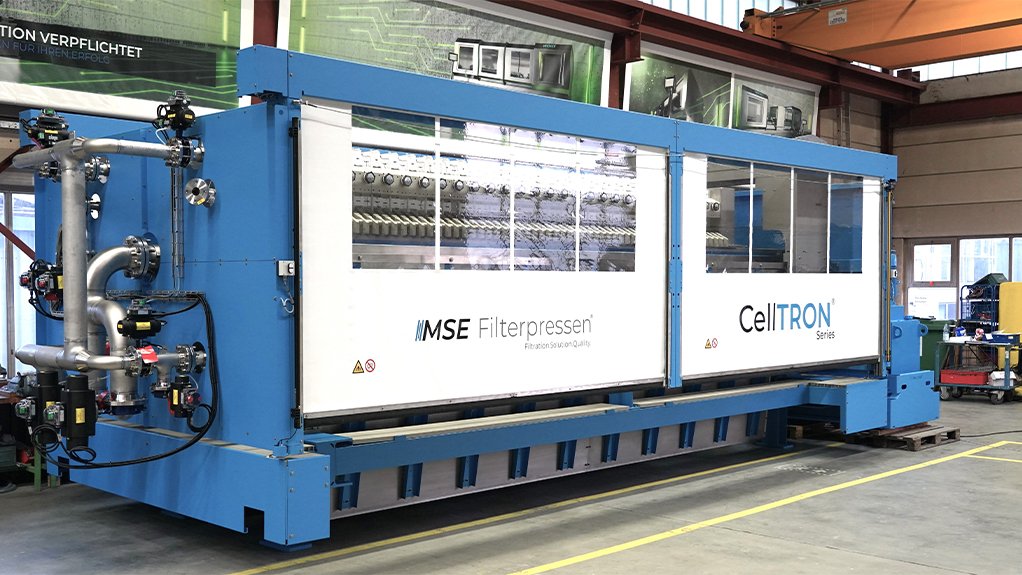

To address this, Nyrstar opted for a solution that could meet both the quantitative and qualitative requirements of the upgraded line. A membrane filter press from German manufacturer MSE Filterpressen was selected to fulfill these specifications. The system is designed to ensure high dewatering performance and stable operation under the specific chemical and process conditions present at the Hobart facility.

Technical Configuration and Adaptation to Site Conditions

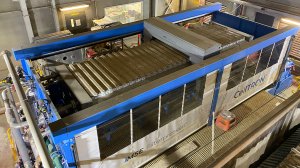

The installed filter press uses membrane filter plates that are mechanically compressed during the filtration cycle. In a secondary step, the membranes are pressurised with water, enabling further reduction of residual moisture content in the filter cake. This enhances not only yield but also downstream handling and disposal efficiency.

To withstand the aggressive process environment, MSE configured the system with PVDF membranes and a duplex stainless-steel lining. The filter press was designed in modular sections to allow transport to Tasmania and to enable space-efficient assembly on site. The configuration also allows for later adjustments, if needed, as operational demands evolve.

Automation and Process Integration

All filtration steps – including slurry feeding, pressure control, plate opening, cake discharge, and filter cloth cleaning – are fully automated. The system’s integrated safety features and sensor-based monitoring help ensure operator protection, especially under the high operating pressures typical in zinc processing. Consistent cycle times contribute to a stable and predictable production rhythm.

Occupational Safety and Environmental Impact

The enclosed design, combined with automated cake removal, minimises operator exposure to acidic residues. The result is improved handling safety and compliance with strict site-level occupational safety protocols. The reduced moisture content of the final product supports more efficient transport and disposal while decreasing overall environmental impact.

Logistics and Implementation

The approximately 40-t unit was shipped in modular components from Germany to Tasmania. The intercontinental transport and on-site installation were closely coordinated between MSE and Nyrstar to ensure alignment with production schedules. Commissioning and technical integration were executed by the manufacturer’s engineering team, with particular consideration given to local spatial constraints.

The deployment of a membrane filter press specifically configured for zinc electrolysis underlines the relevance of customised solid-liquid separation solutions in modern metal production. With experience in similar process environments, MSE Filterpressen contributed targeted engineering expertise to support the plant’s operational goals. The system not only strengthens production stability at Nyrstar Hobart but also reflects broader industry trends toward automation, safety and resource efficiency in hydrometallurgical applications.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation