Global OEMs, smart factories drive efficiencies

NEW-GENERATION TRACKING Digital technology and smart factories will enable clients to track materials such as mined ore that is moved around a factory or mine site

Global original-equipment manufacturers (OEMs) with branches in South Africa could assist in pushing the African continent towards the implementation of Fourth Industrial Revolution (4IR) smart factory technologies. This will increase efficiency and energy savings in the materials, bulk handling and logistics sectors, says automation solutions provider SEW-Eurodrive national sales and marketing manager Norman Maleka.

“At some point, we are forced to adapt. Leading automotive manufacturers, such as BMW and Ford Motor Company, as an example, are introducing new technologies from their head offices to local factories. This compels us, as a local SEW-Eurodrive affiliate, to keep up with the trend. It’s where the industry is shifting,” he explains.

As many factories and plants in South Africa are older, Maleka highlights that expansion of existing, and the building of new, factories are inevitable. Subsequently, local factories can emulate their European counterparts by considering the use of smart technologies.

One of the primary factors driving this shift will be the younger generation, because many engineering graduates will be familiar with the latest digital technologies.

“Everything happens on smart devices, so they would be the generation to drive this requirement. Younger engineers want monitoring, sensors, real-time communication, software, programming if there is an expansion at a factory involving younger engineers, this is what they will specify,” Maleka reiterates.

Enhanced technologies will enable clients to track their products and materials, such as mined ore, that is moved across a mine site to a processing facility.

Integrated tracking will keep clients informed about their products and materials throughout the supply-chain process, including testing and movements by logistics vehicles, supplemented by processes such as tracking.

Maleka notes that much of this tracking process would be communicated using smart devices, particularly through an Ethernet connecting computer systems to a local area network.

Amid a struggling local economy, Maleka emphasises the difficulty in presenting this kind of technology and increased efficiency – considering its significant initial investment – to the mining industry.

The minerals processing and materials handling sectors that rely on processing plants and factories provide an ideal opportunity to present these solutions, primarily because of the energy savings that can be realised.

“We’ve always been talking about energy efficiency – we have an appropriate product portfolio to address that – especially now, when times are tough. If such products had been in use at your plant, you’d be able to minimise energy costs and save in the long term,” Maleka underlines.

Specific departments in companies dedicated to investigating concepts such as energy efficiency and product life cycles have made the presentation of these types of technologies easier, he suggests.

“Adopting efficient 4IR digital technology remains the clients’ responsibility. Some are quick to adapt, while others are more reluctant.”

He attributes this reluctance to there being no pressure locally to adhere to any regulations, as there are no energy efficiency-related standards in place that industry is compelled to comply with.

Maleka cites Japan, which has regulations against the import, selling and use of standard efficiency (IE1) motors in the country and its relevant industries, as an example. The regulations require that machines have at least a premium efficiency (IE3) motor or a later version to encourage the use of more energy efficient machinery.

“Once we adapt to that kind of thinking, we will see more improvement on that front.”

SEW Offering

SEW-Eurodrive has a varied product portfolio for different industries, which includes materials, bulk handling and logistics applications.

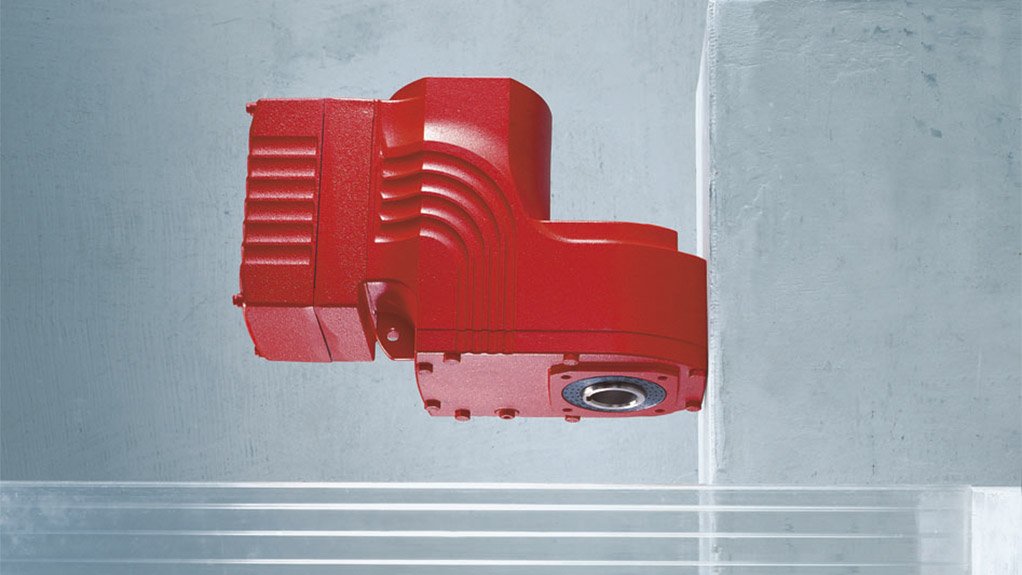

This offering includes the company’s X-Series of industrial gear units. The range is ideal for conveyor belt drives, and has a torque range from 6.8 kNm to 475 kNm. Several accessories allow for flexible use, while a range of gear ratios allows for helical and bevel-helical gear units.

Maleka highlights the gear units’ efficiency and ease-of-use, which are the result of robust housing, low-noise gearing and a cooling system that increases safety.

The units are suited to driving conveyor belts and bucket elevators for the horizontal and vertical transporting of bulk materials.

“What’s also important for the client and these solutions are the lead times, and how quickly we can deliver. Our MOVIGEAR mechatronic drive system is assembled in Cape Town, while some of our industrial gear units are assembled in locations such as Nelspruit. This increases our presence in the country, and shortens the lead time for customers,” Maleka adds.

The units can also be selected for specific applications, including specifying it with an IP69K rating, which provides protection against ingress of dust. The units can also be made to withstand cleaning with detergents after shifts, which would normally be harmful to the units.

“Whenever we advise a client on a solution, we try to consider it from a project planning point of view. We try to understand what our customers are trying to achieve so we can choose the appropriate solution that will address that requirement,” he concludes.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation