Hydrogen economy continuing to build, Implats’ Sifiso Sibiya reports

Implats group executive refining and marketing Sifiso Sibiya.

Implats pioneered hydrogen powered forklifts several years ago at its PGM refinery in Springs.

Photo by Creamer Media

JOHANNESBURG (miningweekly.com) – Momentum in the hydrogen economy is continuing to build, Impala Platinum (Implats) group executive refining and marketing Sifiso Sibiya reported when he presented an Implats slide outlining global market trends for the platinum group metals (PGMs) of the Johannesburg Stock Exchange-listed company, which this week announced half-year free cash flow generation of R11-billion generated after funding capital expenditure of R4.9-billion.

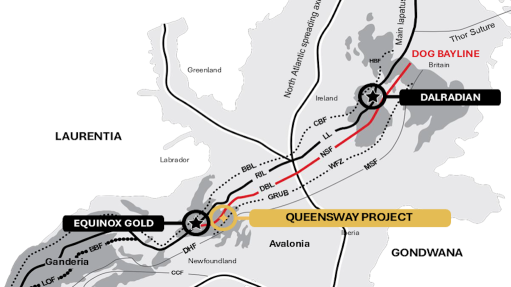

The slide, which highlighted the technological advances that will diversify and support future PGMs demand, singled out hydrogen as a PGMs demand sector which is continuing to gain traction, with demand projections being de-risked and showing improvement.

Mining Weekly can report that green hydrogen and PGMs are joined at the hip from the point of generating the product through proton electron membrane (PEM) electrolysis and then turning the hydrogen back into green electricity with the help of platinum-based fuel cells. These fuel cells then provide the cleanest of clean zero-emission mobility as well as having the capability to generate clean, green stationary electricity.

It is important to recall that Implats pioneered hydrogen-powered forklifts several years ago at its PGMs refinery in Springs. (See above picture.)

Also during its half-year financial and operational results presentation two days before the Implats' presentation, Sibanye-Stillwater CEO Neal Froneman described the hydrogen economy as underpinning the world’s future energy requirements through PGMs.

And a week before that, Anglo American Platinum CEO Natascha Viljoen highlighted the hydrogen space as being “an exploding space”.

Viljoen also drew attention to South Africa’s own hydrogen corridor being declared a Strategic Integrated Project, which is scheduled to get under way this year with 20 hydrogen buses being supplied by three hydrogen trucks. The corridor is expected to eventually create 14 000 jobs and consume 63 000 oz of platinum.

The first trial phase will make use of existing spare green hydrogen capacity at Anglo American Platinum’s Mogalawena PGMs mine, increasing that in 2024 to 50 trucks and 50 buses and then progressing to 500 trucks and 300 buses, with the route extending from Limpopo through Gauteng to KwaZulu-Natal.

“What's important for us as an economy is also the development that we see happening across the world,” said Viljoen, in reference to the global uptake of hydrogen as a future clean universal energy source, which is dependent on PGMs that South Africa hosts so overwhelmingly.

The PGMs are needed to:

- generate green hydrogen;

- turn green hydrogen back into electricity;

- create the green hydrogen to power internal combustion engine (ICE) hydrogen vehicles; and

- potentially also in time significantly lower the weight of batteries used by battery electric vehicles through research that is very well under way.

The lower cost of green hydrogen through EU initiatives has prompted green hydrogen end-use in Uber fleets in Germany, with all global advances of this nature pointing to South Africa's PGMs industry – which employs 500 000 people directly – being boosted as the world transitions away from fossil fuels as part of the global decarbonisation imperative to mitigate climate change.

The hydrogen economy encourages the use of PGMs because PEM electrolysis is ideally suited to the variability of renewable energy. Moreover, the uniqueness of PGMs takes on both temperature and energy variance. This is crucial because of the variable flow of sun and wind energy. This reduces overall cost and improves overall efficiencies, with the key word being overall.

Important to note is that green hydrogen vehicles only need to capture 10% of the future light vehicle market to have the same demand for the sector as today’s ICE vehicles do.

The other point is that hydrogen generation – and the fuel cell electric vehicles that turn the hydrogen back into green electricity – are far less mineral intensive when adjudged from engine to wheel. From a recycling point of view, fuel cell electric vehicles also present a considerably friendlier recycling environment.

GLOBAL GREEN HYDROGEN ADVANCES

Global green hydrogen advances are being made regularly, globally, as the world transitions to clean energy in the fight against climate change.

On February 28, Oslo-based Nel stated that it had taken the final investment decision to expand the production capacity at its PEM electrolyser manufacturing facility in Wallingford, Connecticut, US, to bring annual production capacity towards 500 MW in 2025.

Nel CEO Håkon Volldal described the move as a milestone that would increase PEM production capacity substantially and simultaneously reduce stack cost and improve stack efficiency, with the new production line poised to reach nameplate capacity in 2025.

The development of the 500 MW PEM production line will be a substantial contributor to further expansion plans in the US, where Nel is planning a gigafactory with of up to 4 GW production capacity.

“We’re considering three attractive alternatives in three different states and will make a final decision shortly,” Volldal revealed.

Nel is also expanding in Norway, where production capacity is expected to reach 1 GW in April 2024.

“During the last months, we have received significant purchase orders for large-scale electrolyser projects. Therefore, we have ramped up production from three to five shifts, meaning that production is now running around the clock, also on the weekends,” added Volldal.

Also on February 28, European green hydrogen energy company Everfuel and hydrogen infrastructure funder Hy24 announced a joint venture (JV) to finance the accelerated development of electrolyser capacity across the Nordics. Everfuel will own 51% and the Hy24-managed Clean H2 Infra Fund the remaining 49%.

Everfuel founder and CEO Jacob Krogsgaard described the JV as a means of making green hydrogen commercially available through an accelerated deployment of hydrogen hubs, a view shared by Hy24 cofounder and CEO Pierre-Etienne Franc.

Denmark Foreign Affairs Minister Lars Løkke Rasmussen forecast that green hydrogen would play a major role in decarbonising shipping, aviation and heavy transportation.

The hydrogen plants owned and operated by the Everfuel Hy24 JV are committed to supporting the Danish hydrogen roadmap, which involves the creation of 4 GW to 6 GW of electrolyser production capacity by 2030, to leverage Denmark’s strong wind resources. Everfuel’s current project portfolio in Denmark already includes 1.3 GW of electrolyser capacity.

UK-based zero-emission truck manufacturer Tevva Hydrogen Electric Trucks has revealed that its hydrogen-electric prototype has racked up just shy of 350 miles on a single charge. The 7.5-tonne dual-energy vehicle is fitted with a hydrogen fuel cell range extender.

Meanwhile, the JV between the Swiss company H2 Energy Europe and the filling station operator Phillips 66 is to build 250 hydrogen refuelling stations in Germany, Austria and Denmark, the first ten of which are due to be completed by 2024. These will refuel cars as well as light and heavy commercial vehicles and buses with gaseous green hydrogen at 350 and 700 bar.

While most of the refuelling stations will be newly built, some will be the expansion of existing conventional Jet stations.

Japan, which has led in hydrogen for many decades, is finding itself joined by many other economies, while still featuring strongly in the pursuit of making the world a better place through the embrace of green hydrogen. Hydrogen Council executive director Daryl Wilson recently provided keynote address to a panel at the Japan Energy Summit in Tokyo.

In the UK, Birmingham Airport has signed a partnership agreement with ZeroAvia to focus on introducing on-airfield hydrogen refuelling and regular domestic passenger flights using zero-emission aircraft, World Platinum Investment Council (WPIC) has reported.

ZeroAvia’s first trial flight of a 19-seater passenger aircraft powered by hydrogen fuel cells took place in January. With the backing of Amazon, Bill Gates and Shell, the startup is working on bringing to market a zero-emission system capable of flying a 20-seat aircraft by 2025.

The German town of Wesseling is, according to the WPIC, introducing a cleaner and greener future with hydrogen fuel cell buses doing public transportation.

Local public transportation company Regionalverkehr Köln GmbH (RVK) reportedly now operates in the town exclusively with the fuel cell buses, replacing traditional internal combustion engine buses.

RVK is said to have Europe’s largest fleet of hydrogen-powered Solaris buses, making Wesseling a leader in the adoption of hydrogen bus transport.

Moreover, hydrogen trains some time ago entered passenger service fray on a line west of Hamburg, Germany, and in Scotland, hydrogen trains are becoming a reality after numerous test runs.

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation