Industry faces skills shortage

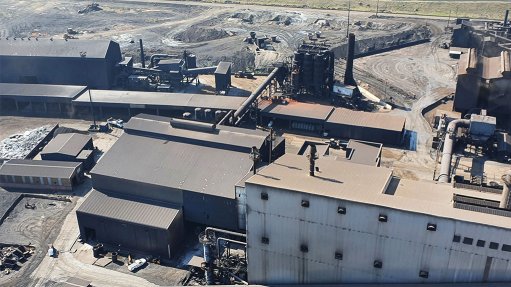

CAROL BRANDT Prisma has provided training solutions for flotation plants in the platinum mining industry, with a noticeable increase in metal recovery once training was completed

JACQUES FARMER To address the demand for skills, Prisma has established learnership programmes for metallurgy operators

There is a significant need to upskill equipment operators in the metallurgy sector as they often do not receive formal training, says specialist mining training provider Prisma Training Solutions metallurgy training manager Carol Brandt.

She adds that a skills gap exists for graduates leaving university and entering the workplace, necessitating graduate training programmes to prepare them.

“Metallurgical skills have been placed on the list of scarce skills by various Sector Education and Training Authorities since the passing of the National Skills Development Act in 1998. It is important that equipment operators understand physics, and chemical and engineering processes to make better decisions when working a shift.”

To address the demand for skills, Prisma has established learnership programmes for metallurgy operators to provide them with further education and training, a certificate in mineral processing and an articulation of credits.

The company introduced its minerals processing department in 2019 after acquiring consulting house Talent Factor.

Talent Factor had a mineral processing accreditation, and Brandt says introducing mineral processing courses became relevant to accommodate the consultancy’s clients in the mining industry.

Prisma MD Jacques Farmer adds that the acquisition enabled Prisma to offer a “full complement of turnkey solutions” for clients and encourage women empowerment in the company’s minerals processing department.

“We wanted to bring more women into the company, and we are proud to say that this department is run by women. [Brandt] oversees the minerals processing department with learnership specialists, skills programme specialists, data capturers and trainers – the majority of which are women – under her command,” he says.

Minerals processing training takes place at a client’s site, owing to every plant and the relevant equipment being unique.

Training comprises applying theoretical knowledge in practical situations, while the programmes are concluded using practical assessments at a client’s plant using its equipment.

Thereafter learners receive a competence certificate or the relevant qualification.

Training Relevance

Brandt says safety training is necessary because mining companies are obligated to record their safety statistics.

Additionally, an equipment operator’s level of understanding directly impacts on the key performance indicators (KPIs) of a mining operation which, in turn, affects the company’s financial metrics.

Prisma has provided training solutions for flotation plants in the platinum mining industry, with a noticeable increase in metal recovery once training was completed, she comments.

“While return on investment from training can be difficult to prove, the KPIs observed in mineral processing shows a direct benefit through increased recoveries and production tonnage,” she explains.

Farmer adds that it is also relevant to consider the human capital development aspect of training, which focuses on developing soft skills that assist with morale building among metallurgists and plant operators.

Meanwhile, Prisma aims to expand its service offering to industries such as pharmaceuticals and metals production.

“Our team in mineral processing is passionate about educating and uplifting the skills of plant operators because many of them did not get an opportunity to study, although they have been working for many years.

“Being able to provide them with a theoretical understanding of what the process entails really can change the lives of people working in mineral processing plants. “The passion for uplifting those skills is what keeps us going and will take us from strength to strength in the future,” concludes Brandt.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation