Operational readiness is key to PDS implementation on mines

Anton Lourens, CEO of Booyco Electronics

Level 9 vehicle intervention technology is designed to automatically slow or stop machines, reducing the risk of collisions in mining environments

Proximity detection systems (PDS) provide a powerful tool to protect both pedestrians and operators in high-risk trackless mining machine areas

Successful implementation of Level 9 systems depends on thorough risk assessment and alignment with each mine’s traffic management plan

Operational readiness for PDS roll-outs requires collaboration across management, engineering, production, finance and human resources

Change management and operator training are critical to achieving the full safety benefits intended by the Level 9 collision avoidance regulations

This article has been supplied.

Level 9 vehicle intervention for collision avoidance has been mandatory on South African mines since 2022, yet the effective roll-out of proximity detection systems (PDS) remains slower than expected - not due to technical limitations insofar as integration but to operational readiness on site, says Booyco Electronics CEO, Anton Lourens.

The Level 9 requirements mandate engineering controls on trackless mining machines (TMMs) to automatically slow down or stop vehicles, preventing both machine-to-pedestrian and machine-to-machine collisions. While PDS technology has advanced considerably to meet these requirements, Lourens stresses that a real challenge lies in how mines prepare to integrate it.

“Many operations are still not ready to operationalise PDS within their daily activities, safety systems or workflows,” he explains. “Successful adoption demands coordinated involvement from all stakeholders including the mine’s own management, operators and departments, regulators, technology suppliers and TMM OEMs.”

Detailed risk assessments remain a key requirement for mines to identify and mitigate significant hazards, specifically around TMMs. Lourens notes that PDS is a valuable tool in this process of mitigation that can provide valuable information, but its implementation must be systematic and aligned to the broader risk framework.

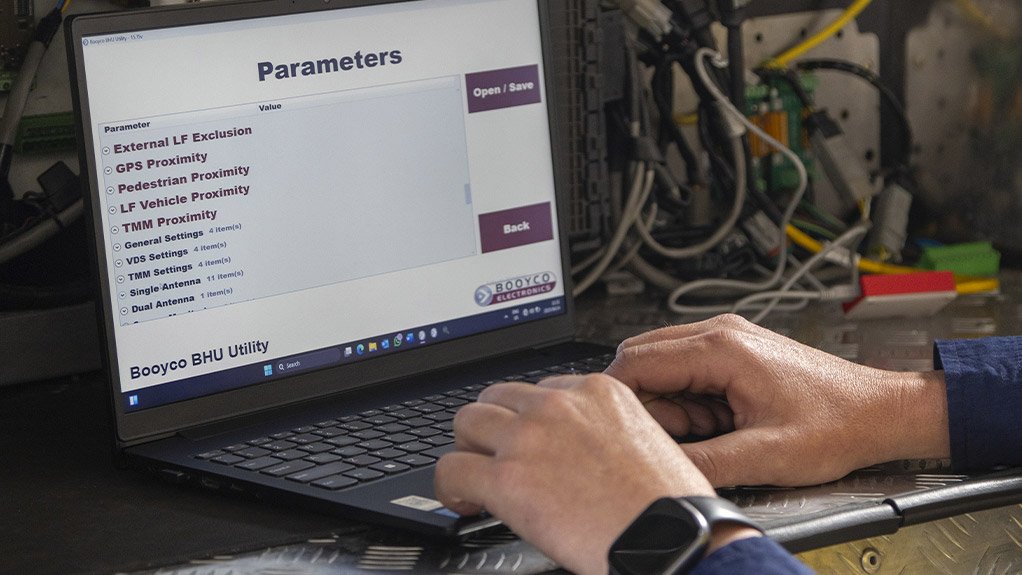

The choice of PDS technology will depend on the specific environment and based on identified risks - whether underground or surface, hard rock or coal - but it must be introduced without creating further unintended risks to other operational systems, particularly production.

A critical starting point, he says, includes the mine’s traffic management plan. Reducing vehicle-pedestrian interaction lowers risk and minimises production disruption. Continuous analysis of incident hotspots can guide traffic flow adjustments and sometimes operational plans may need to be revised. Once traffic patterns are optimised, PDS deployments can be aligned to complement these flows. Misalignment risks frustrating operators, creating “PDS fatigue” from excessive warnings which can lead to alerts being ignored.

Operational readiness, therefore, requires full leadership commitment and cross-functional collaboration. While PDS suppliers often deal with engineering teams, Lourens points out that production, finance and human resources must also be engaged. Finance teams need to weigh capital and maintenance costs against safety and efficiency benefits; HR must oversee operator training and production must understand the operational implications.

Change management, he warns, is neither quick nor easy. It requires active communication across the mining ecosystem, ensuring that everyone understands the system’s function and value. “Any new system must be accompanied by a change in behaviour or nothing will improve,” he says. “Unlike when introducing mechanical equipment some PDS operates invisibly through radio frequencies (RFID) so early engagement, clear communication and thorough training are essential.”

From induction and operator instruction to ongoing best practice reinforcement, Lourens concludes that mines must take a structured inclusive approach to PDS adoption if they are to achieve the full safety benefits envisaged by the Level 9 regulations.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation