Unearthing efficiency in the Mining Industry with leading solutions from Festo

This article has been supplied.

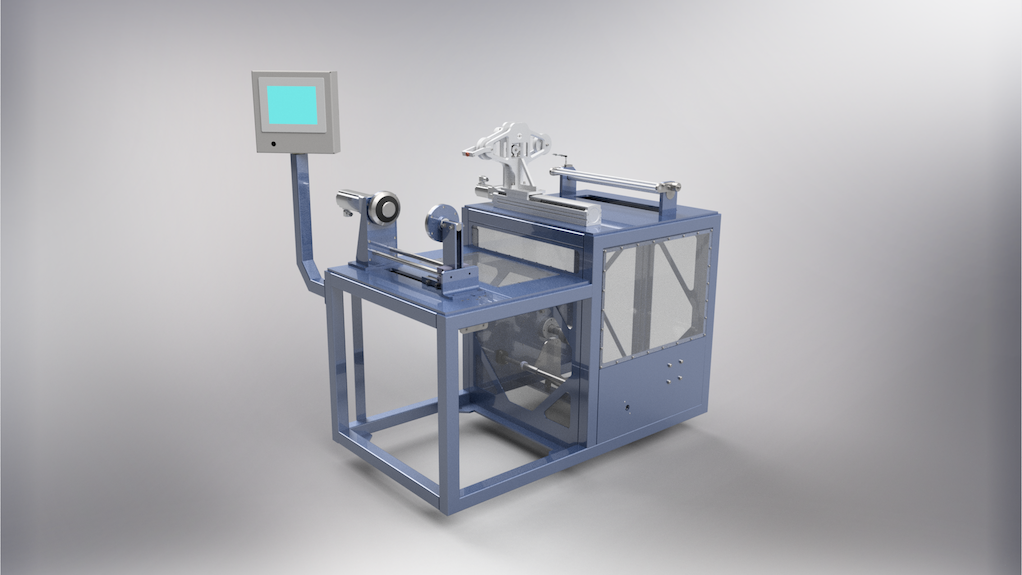

In the Mining Industry, the use of a reliable detonator cord winder can be the difference between a successful, profitable and safe operation or a disaster. Without the proper equipment, the cord used to initiate the blasting process can be difficult to manage, leading to a greater risk of accidents. However, by paying close attention to the quality of the cord winder, mining operations can avoid this whilst significantly improving their efficiency and profitability.

In efforts to deliver a reliable detonator cord winder for a distinguished end-user within the mining industry, Qualitec Engineering sought out an established company to commission and program this device. After thorough review and consideration, the renowned System Integrator chose Festo South Africa to undertake the challenge due to their extensive industry experience and product range.

"Over the past 30 years, we have created numerous solutions for leading corporations. As we advance into the fourth industrial revolution, we seek a partner who shares our ambition to design and manufacture solutions for the future," said Marius van Niekerk, Lead Technical Designer at Qualitec. "I believe that Festo is at the forefront of innovation and quality in the industry. Their ability to service our needs from start to finish made them stand out from the rest," he added as he elaborated on why they chose Festo for this project.

Thanks to the leading automation company's state-of-the-art automation products, the machine was designed, tested and commissioned with accuracy. "Working with a strong mechanical design company like Qualitec Engineering made the integration and commissioning easy. The development of the mechanical, electrical, and software components proceeded seamlessly," said Werner Das, Festo Automation Engineer.

Automating the device with Festo cutting-edge technology

The Festo Motion Controller CPX-E is a powerful system that is becoming increasingly popular in the industry due to its advanced algorithms and flexibility in various applications. In this project, the CPX-E was used to control the winding process of a cord, monitoring the process and adjusting the speed and tension as needed to ensure proper winding. The controller also has the ability to stop the process if it detects any issues, such as a break in the cord or an obstruction in the path.

In this innovative project, the CMMT-AS Servo drive played a crucial role in ensuring a smooth winding process. The drive seamlessly received control commands from the Motion Controller CPX-E and then expertly converted them into the exact voltage, current, and frequency needed to operate the motor. This control ensured that the motor received the perfect amount of power to wind the cord in the desired direction and speed. The CMMT-AS's ability to provide power and control signals to the motor made it a vital component of the winding process, and it's easy to see why this drive is becoming an industry favourite.

Offering outstanding performance and value, the Festo Valve Terminal VTUG is a game-changer in the winding industry for end users. Its ability to control the flow of air and pressure to the actuators allowed quick clamping and lifting of the coil. This valve terminal also offers easy installation, with its multiple multi-pin variants and simple connection options for standard fieldbuses and IO-Link®, making it perfect for high pneumatic functionality and electric modularity.

Adding to this game changer is the Controller CDPX, which offers a powerful solution for monitoring and controlling the winding process in real-time. It provides operators with a clear view of the current status of the process, allowing them to easily make adjustments as needed. Its HMI allows operators to keep an eye on the winding process and gives them the information they need to make decisions quickly and efficiently.

The Proportional Valve Regulator VPPM is engineered to seamlessly connect with IO-Link, an industrial communication protocol that allows the valve to communicate with other devices on the network, such as PLCs, sensors and stepper drives. This valve is responsible for controlling the brake of the large unwinding spindle from which the cord is unwinded, ensuring that the process runs smoothly. With the VPPM IO-Link proportional valve regulator in place, the end user can rest easy knowing that their unwinding process is in good hands.

Online calculation tools

Festo online calculation tools greatly reduced the design and commissioning times for Qualitec. One particularly useful tool was the Electric Motion Sizing tool, which helped them find the perfect electric servo drive for their application. The tool only requires a small number of parameters, such as mass, stroke/travel distance, and cycle time, to calculate and promptly tell the user which solution is the most economical for their requirements - guaranteeing results.

As an added bonus, the tool also exports the calculated parameters directly into the Festo Automation Suite programming software. This software not only combines parameterisation, programming and maintenance of Festo components into one program, but it also enables the entire drive package - from the mechanical system to the controller to be commissioned seamlessly. It makes industrial automation simple, efficient, and hassle-free.

Qualitec's partnership with Festo has been highly successful. This joint venture has enabled them to produce an industry-leading solution that has the ability to compete on a global level. "As a team, our confidence in undertaking future projects has been bolstered by the knowledge that we have unwavering support from Festo", concluded Marius.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation