Welding Alloys South Africa

The loss of material owing to wear is costing the mining industry billions of dollars every year. Abrasive wear occurs when small pieces of material are forcefully removed from the surface of steel and other liners as feedstock passes through a chute, for example. Over time, the liner thickness is reduced as a result and eventually needs replacement. The rate at which the liners are worn and the frequency at which they need replacing are functions of the throughput of operations, and the ability of the liner material to combat the removal of material from its surface.

It is a known fact that longer-lasting liners reduce the total cost of ownership, which can be calculated by dividing the total cost of the liner system by the total production tonnage.

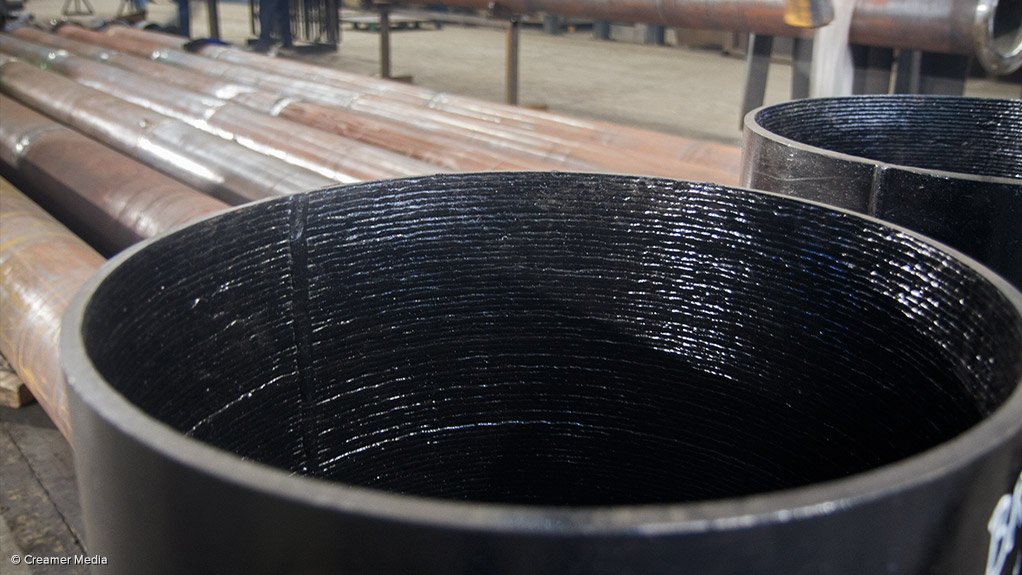

Welding Alloys South Africa (WASA) produces an extensive range of chromium-carbide overlay plate at its Benoni facility in South Africa. These plates are produced using automated equipment and best-practice methods to ensure consistent high quality in line with Welding Alloys Group’s global standards, rating WASA’s products among the most wear resistant on the market today.

WASA’s chromium-carbide plate is produced in six variants, including high-temperature applications, extreme abrasive wear, high-impact and light weight liners with ultrahigh wear-resistant properties.

Besides liner applications and fabrications, WASA also refurbishes worn components by means of rebuilding, hardfacing and ceramics to provide its customers with the most cost-effective solutions to keep wear parts operating for longer.

“Our team of sales and technical experts regularly conduct wear audits. The information from these audits is used to provide specialised

solutions to our customers in the mining industry to enable them to keep plant and equipment running at optimum production rates for extended periods.

“When the ‘WEARwolf’ keeps you awake at night, we are your Go-To Provider of Engineered Wear-Protection Solutions.”

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation