Babcock in Africa: 135 years of steam generation and associated technology

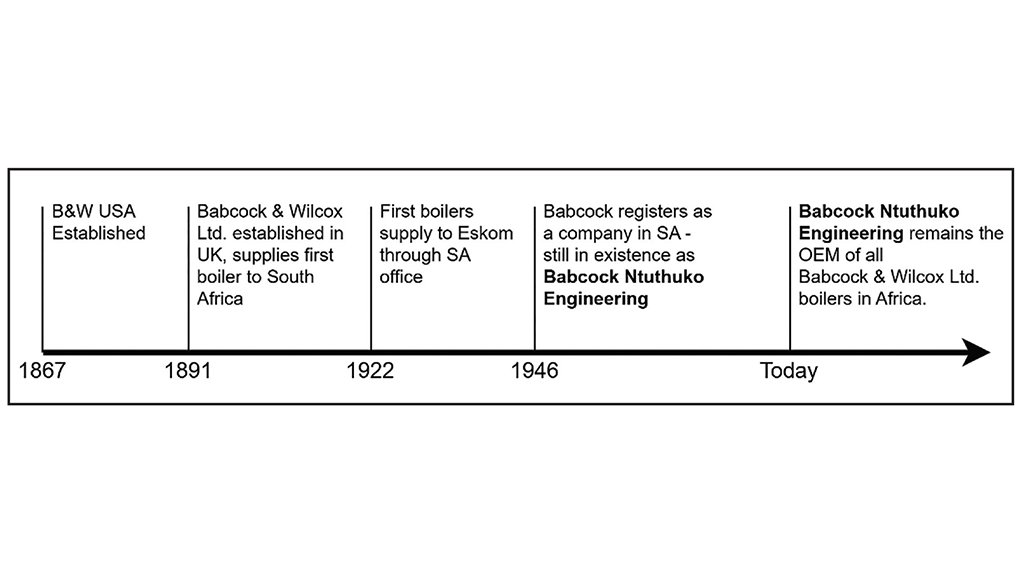

Few companies can claim a legacy in Africa as deep and enduring as Babcock, which is known globally for pioneering boiler and power generation technology since the 19th century.

Babcock established itself in South Africa as the steam generating technology leader in the 1890s through its initial supply of steam to the De Beers group of diamond mines.

This marked the start of the energy story of South Africa becoming inseparably linked with the history of Babcock boilers amid a central ongoing shaping of South Africa’s energy infrastructure.

For 135 years, Babcock has been designing, supplying, maintaining and modernising the equipment that keeps South Africa’s power plants and industries in operation.

Globally, Babcock & Wilcox (B&W) has led innovations in boiler design and environmental technology, from low-NOx burners to waste-heat recovery and advanced combustion systems – contributions that have shaped the power sector worldwide.

Since its formal registration in 1946, Babcock Africa has been the custodian and original-equipment manufacturer (OEM) of Babcock-designed boilers across the continent, bridging global innovation with local implementation.

In South Africa, Babcock Africa ensures that these technologies are successfully applied, adapted and sustained.

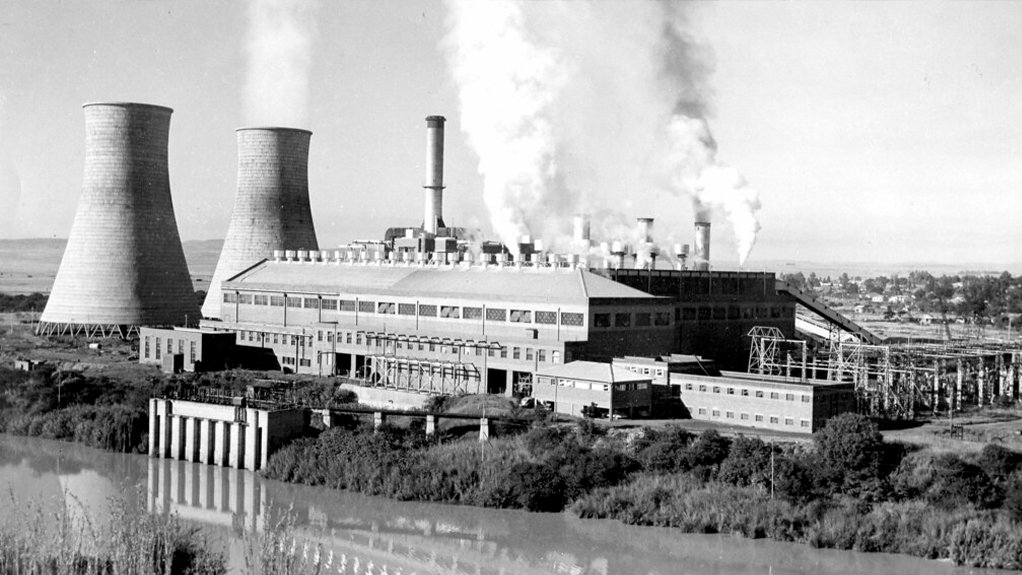

In the 1940s and 1950s, an integral role was played in Eskom’s first centralised power stations at Witbank, Brakpan and Congella.

From 1970 to 1990, major utility boilers were designed and commissioned at Eskom’s Grootvlei, Hendrina, Matla and Lethabo power stations and many are still in service today.

The 2000s led to the formation of Babcock Ntuthuko Engineering, the empowered engineering division of Babcock Africa (through partnership with Sphere Holdings).

Building on Babcock’s original operations in South Africa, Babcock Ntuthuko Engineering continues to specialise in lifecycle management, life extension and emissions-reduction retrofits.

As the OEM of all Babcock boilers in the Eskom fleet and all boilers in Africa supplied through B&W, Babcock Ntuthuko Engineering has remained deeply involved in boiler design, maintenance and engineering solutions of Eskom’s coal-fired fleet, as well as various industrial projects, while its Babcock International Group Africa Division parent company diversified the business, which by then included heavy fabrication works, plant and welding equipment services, heavy machinery distribution, industrial generators, training services and truck transport solutions.

Project achievements during this time spanned various industries and included a coal/bagasse boiler in Swaziland; waste heat boilers in Vanderbijlpark; a unique multi-fuel fluidised bed boiler in Durban; fluid-bed conversion for wood waste; refurbishment of a sugar mill in Mozambique; and high energy piping systems (replacement and new build) for Eskom.

Technologies for the Future

With the introduction of new emission regulations in the 2020s, Babcock Ntuthuko Engineering further broadened its footprint by being awarded a low-NOx burner project at a large petrochemical site.

This included integration of low-NOx burner technology supplied to Babcock Ntuthuko Engineering by their technology partner. With these, NOx emissions were reduced from 1 100 mg/Nm³ to just 470 mg/Nm³, well below the regulatory threshold of 750 mg/Nm³ in a project that marked one of the first successful NOx reduction efforts in South Africa.

This project continues to deliver huge success, with eight boilers retrofitted and tested by August 2025 sustainably producing up to 50% NOx emission reduction.

Extending into abatement solutions for particulate emissions, Babcock Ntuthuko Engineering was awarded a multi-unit electrostatic precipitator (ESP) upgrade and refurbishment contract, also integrating and supported by their technology partners.

With each unit rated at 600 MW, the total fly ash loading exceeds 100 t/h at full load and particulate emissions have been reduced well below the target for each of the completed units, enabling compliance with the latest air quality regulations for what are some of the largest ESPs in the world.

Emissions control technologies on offer include fabric filters, wet and dry flue gas desulphurisation equipment, and dry sorbent injection systems for sulphur dioxide reduction, to help clients meet the new regulatory challenges.

Capability Beyond Supply of Technology

The capability of Babcock Ntuthuko Engineering to extend well beyond the supply of technology lies in its ability to integrate a wide range of technologies into steam-generating systems, whether for repairs, life-extension maintenance, performance upgrades, or complete new-build projects.

Leveraging the depth of experience of its capable team, Babcock Ntuthuko Engineering can incorporate technology from international suppliers or equivalent alternatives, ensuring that the solution is optimised for the specific operational and client requirements.

This involves performing advanced integration engineering, such as structural modifications, pressure part redesign, thermal performance assessments, and control system harmonisation, to deliver a fully functional and reliable system.

Where the technology owner’s scope typically ends at supplying the technology, Babcock Ntuthuko Engineering ensures end-to-end implementation — adapting, integrating and commissioning the technology to achieve guaranteed operational performance and long-term plant reliability.

Skills Development and Localisation

While global technology providers play a vital role in innovation, Babcock Africa ensures these solutions are embedded locally through investment in people, small, medium-sized and micro enterprises (SMEs) and communities.

Babcock Africa, which strives to ensure that ownership, skills and supply chains remain firmly rooted in South Africa, offers over 200 bursaries and apprenticeships yearly.

In addition, Babcock Africa has a partnership with the Presidential Employment Stimulus to rebuild artisan skills, delivers Enterprise and Supplier Development initiatives in support of black youth- and women-owned SMEs, and integrates local suppliers into critical projects.

This approach ensures not only plant reliability, but also jobs, skills transfer and inclusive growth, which are outcomes that are aligned with the transformation priorities of private and government stakeholders.

By combining global technology leadership with Babcock Africa’s local engineering expertise and workforce development, South Africa benefits from solutions that are globally innovative yet locally sustained. This partnership approach ensures safe, efficient and environmentally-compliant boilers across industries.

From the earliest mines to today’s megaprojects, Babcock Africa remains the constant partner in South Africa’s engineering journey. While working alongside global innovators

Babcock ensures that technologies are not only introduced, but successfully integrated, localised and sustained.

This is ‘lifetime engineering’ in practice – a legacy of innovation, environmental leadership, and skills development that continues to secure South Africa’s long-term energy and industrial future.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation