Company celebrates one year of zero harm

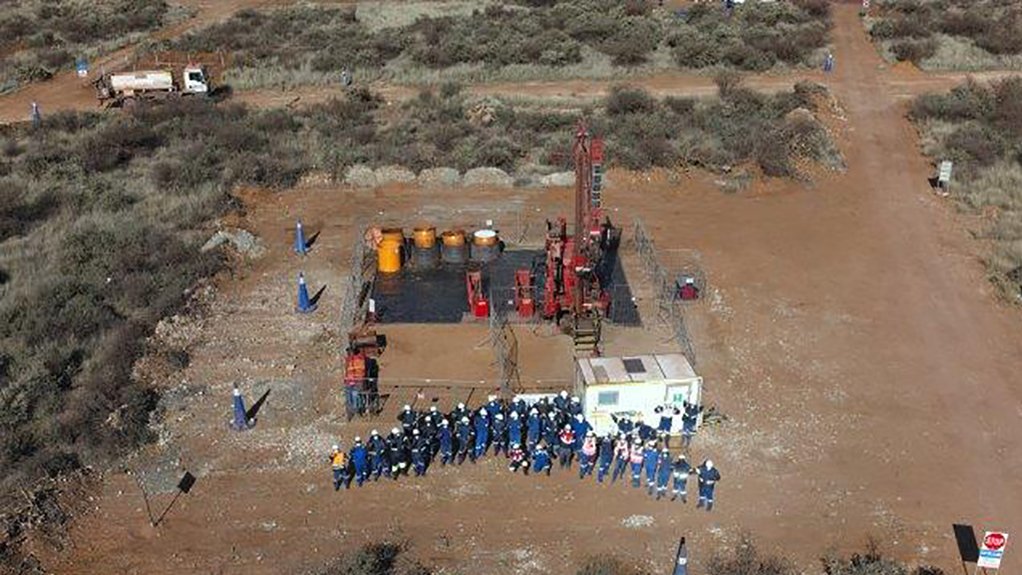

Drilling technology solutions provider Rosond, based in Midrand, has celebrated a year of zero harm at its diamond drilling operation at mining company Kumba Iron Ore’s Sishen mine, near Kathu, in the Northern Cape.

Rosond senior site manager Clayton Coetzee attributes the achievement to close cooperation between department heads, line management, and health and safety executive officers in continually improving standards.

“We always try to improve our processes and strive to make the working environment safer and easier to manage. Employee suggestions and input is encouraged, together with client interaction. We are all in this together, and together we truly can make a difference,” says Coetzee.

“The biggest contributing factor to this achievement is that we are truly our sister’s and brother’s keeper, meaning we always look after each other’s safety and wellbeing,” adds Rosond safety manager Andre Kleynhans.

He elaborates that a culture of caring and responsibility is inculcated on-site, which allows anyone at any time to stop somebody who is doing something unsafe, so that nobody is injured.

“At the end of the day we all go home safe to our families,” says Kleynhans.

He explains that the new drill rig technology that Rosond has introduced at Kumba has played a major role in safe operations, especially in carrying out hazardous tasks such as handling drill rods, which is now automated. As a result, Rosond has successfully trained female drill rig team members at Kumba.

“We are very proud of our safety culture and aim to keep our employees safe at all times,” concludes Rosond MD Ricardo Ribeiro.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation