Environmental Protection A Bonus With IPR’s Slurrysucker®

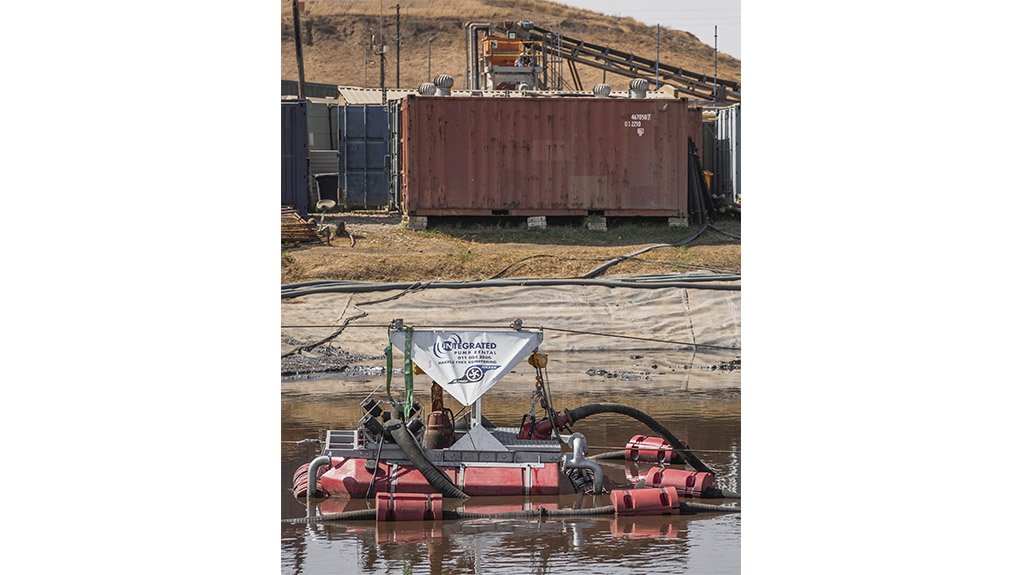

Slurry and dewatering pump specialist Integrated Pump Rental’s SlurrySucker® slurry removal solution can effectively ensure mine and industrial water contaminated sites do not negatively affect surrounding areas.

The need to incorporate environmental preservation techniques on site has become an ongoing and critical action point for the global mining and industrial sectors. Ensuring water contaminated spaces do not negatively affect surrounding areas is one such area where slurry and dewatering pump specialist Integrated Pump Rental can assist through its SlurrySucker® slurry removal solution.

Not only does Integrated Pump Rentals’ SlurrySucker® dredging system effectively clean process water ponds, return water dams or other water storage areas, it has become recognised as an ideal solution for cleaning water capture areas where silt or slimes is an issue or where water retention and water holding capacity is being threatened. Some of these areas are environmentally sensitive and must be protected from causing any pollution.

“Through our SlurrySucker® product range, we are now able to offer a complete solution to effectively remove slurry from any water-based environment and in so doing now offer one of the most cost effective solutions for any dam cleaning project,” says Lee Vine, managing director for Integrated Pump Rental.

The benefits of the SlurrySucker® extend well beyond improving mines’ environmental footprints. They enable increased water storage, the recovery of minerals and improved processing water quality.

“They further make it significantly easier to extend the life of water-dedicated assets by for example protecting dam plastic liners. Clients are consequently able to incorporate slurry removal projects into their planning in order to extract greater value from all non-mining areas,” Vine outlines.

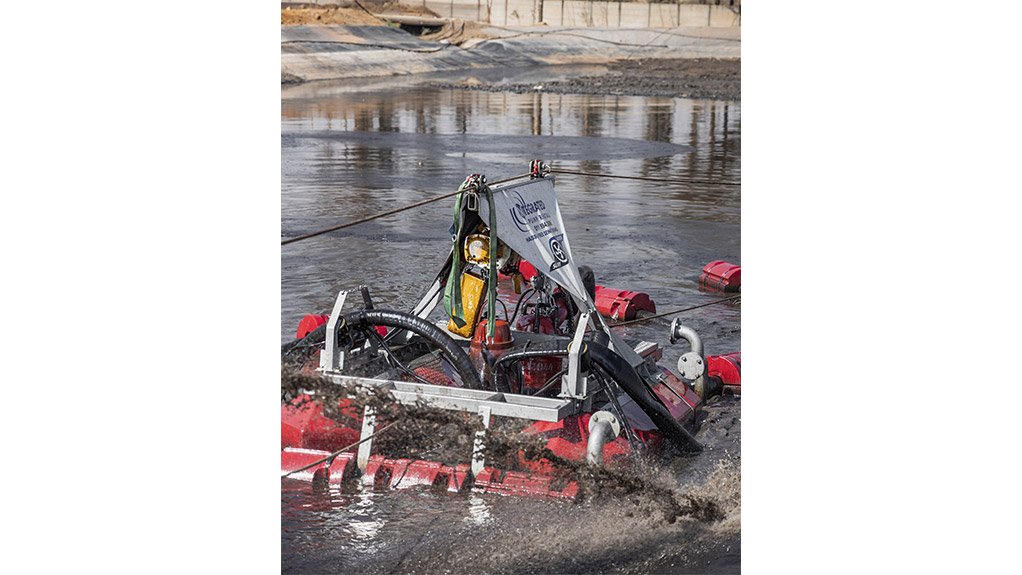

The SlurrySucker® dredge system incorporates world renowned Grindex slurry pumps, making it the most efficient and cost effective electrically powered floating dredge system designed on the market.

Bodies of water, such as ponds, lagoons, dams and canals should be considered valuable plant assets and must be maintained to maximise their operational efficiency and contribution to optimised operational performance and the SlurrySucker® will deliver in this area without fail,” Vine confirms.

The SlurrySucker® is sized to meet the clients’ slurry removal requirements in terms of particle size, aggregation, distribution, cohesiveness, flow characteristics, sedimentation rates and specific gravity. Typical suction water agitation dredging usually achieves 20% - 30% solids for SGs up to 3.0.

Vine highlights two product options – the Maxi SlurrySucker® which is capable of moving 250 m³ an hour at 20% - 30% by volume – equivalent of approximately 70 dry tons per hour. The Mini SlurrySucker® operates at 100 m³ an hour, again at 20% - 30% by volume for roughly 30 dry tons every hour.

Whether it is short-term pond clean-ups or ongoing pond management projects, the SlurrySucker® is designed for difficult site conditions for many applications including:

- Mining – Process ponds, pits, tailings storage

- Energy – Power stations, oil refineries

- Industry – Chemical storage ponds

- Storm water – Sedimentation dams

“We believe the SlurrySucker® is the easiest method of dredging thanks to remote controlled height adjustment of the primary slurry pump and dredge head assembly,” says Vine.

The SlurrySucker® comes standard with galvanised frame structure and Integrated Pump Rental’s flexible design provides the optionality for stainless steel with polyethylene and UV-stabilised pontoons.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation