Firm produces waste steel for global markets, enhances operations

DR MEHRAN ZARREBINI Dr Zarrebini believes that reducing the reliance on the import of tyre-derived steel and the local sourcing of this material will be beneficial for business, industry and the mining sector

Despite the lack of a local market for tyre-derived steel, South African tyre recycling company Mathe Group is changing the way in which waste steel is processed, producing two types of recycled steel, derived from the steel components in tyres, which it exports as scrap steel to foreign markets.

Mathe Group CEO Dr Mehran Zarrebini believes that an increase in interest from local business, industry and the mining sector in using scrap steel will be beneficial for companies such as Mathe Group as this will help diversify its customer base and reduce its reliance on the export of tyre-derived steel.

“There is no doubt that the sector is under pressure, but demand in the local market would [enable] tyre recycling companies to sell their product to local steel processors.”

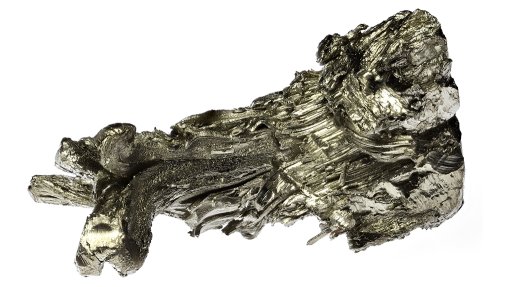

The first variation tyre-derived steel produced by the company is de-beaded steel, which entails removing steel from the sidewalls and compressing it into a bale.

The second entails removing steel from inside the radial truck tyre during the recycling process, which is then refined into processed steel and cut into small pieces.

“Since our operation started in 2016, the amount of scrap steel demanded by the local market has been minimal. There is an increase in demand in the international market, particularly in South-East Asia and India,” Zarrebini points out.

Mathe Group recycles about 700 radial steel truck tyres daily, producing 30 t of rubber crumb. Every truck tyre – which weighs 55 kg – produces 70% of rubber crumb and 30% of waste steel, which is exported through the Port of Durban, in KwaZulu- Natal.

The rubber crumb is used in the manufacturing of products such as acoustic underlays and cradles for infrastructure flooring, nonslip paving, ballistic products and gym mats. It is also used to produce bitumen, an ingredient used to mould parts in the automotive industry, as well as to resurface roads, retread tyres and manufacture brake linings.

However, Zarrebini notes that the delays at South African ports, “onerous” export requirements for tyre-derived steel, and the complexity of obtaining permits and facilitating export duty payments, are challenges that could be averted or addressed through an improved local market for tyre-derived steel.

Further, Mathe Group will make greater investments in innovative machinery and equipment to ensure that there is minimal rubber contamination in steel products, which will ensure “higher-grade” steel products.

“The higher-grade steel will, therefore, be more beneficial to many of the foundries that it is supplied to, and [can] also demand a higher price on the international market,” he enthuses.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation