KFP Rail’s fishplate tech thwarts derailments during local mine trial

Johannesburg-based railway technology developer KFP Rail’s patented fishplate solution has been successfully trialled at a local mine, resolving uneven rail head thickness and, thereby, preventing derailments underground.

“The mining industry faces many restrictions regarding maintenance and access to workings underground. As a result, new techniques and products need to be applied to historic problems,” says KFP Rail project manager Craig Penn-Clarke.

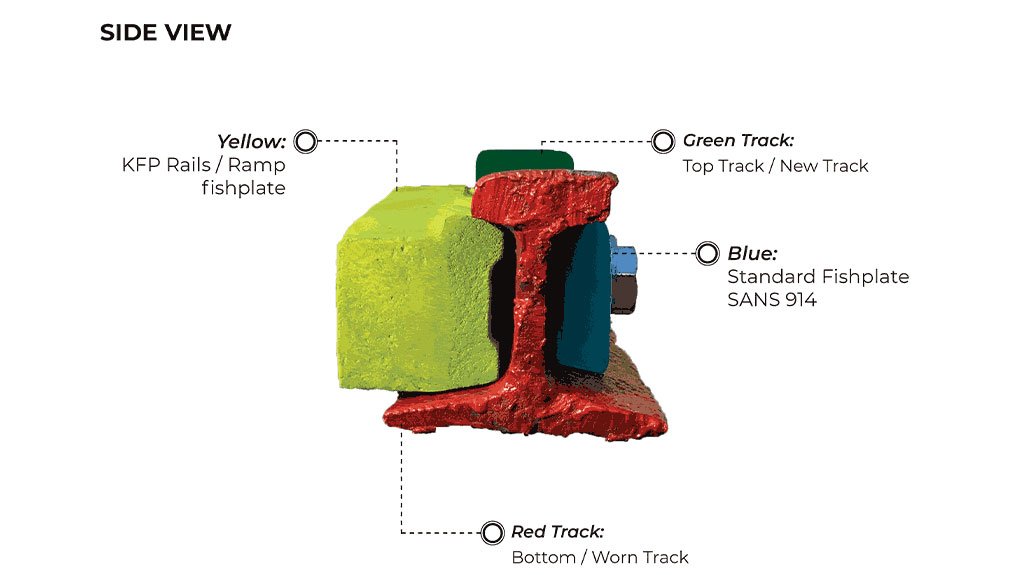

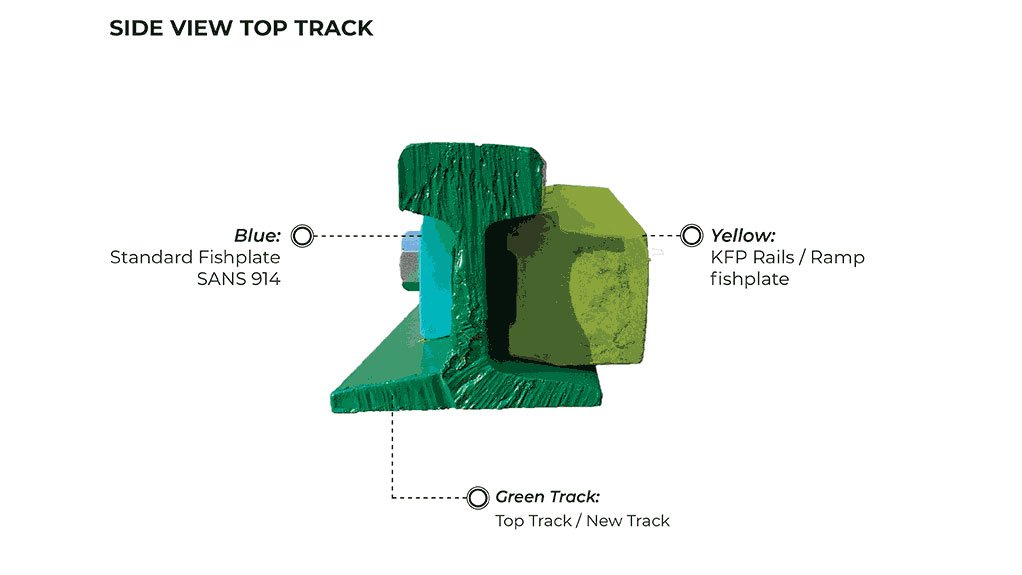

He explains that when an existing rail, which has possibly been operating for decades, eventually breaks owing to wear, or cannot be used anymore, for whatever reason, a new rail is used to replace that existing, now obsolete rail length.

“This new rail, is fitted between two already worn rails, which results in a height difference that causes impact on the wheel and enhances the probability of derailments.”

KFP initiated the development of its Standard Fish^Plate, Ramp Ready Fish^Plate and Ramp Ready Accessory after being approached to create a solution to address uneven rail head thickness by a local major mining house, which it had previously worked with.

The mine searched for a solution but could not find a product that addressed its problem and followed its design criteria, which required a cost-effective solution that involved no cutting, grinding and welding during installation, minimal corrective effort and no delays in production.

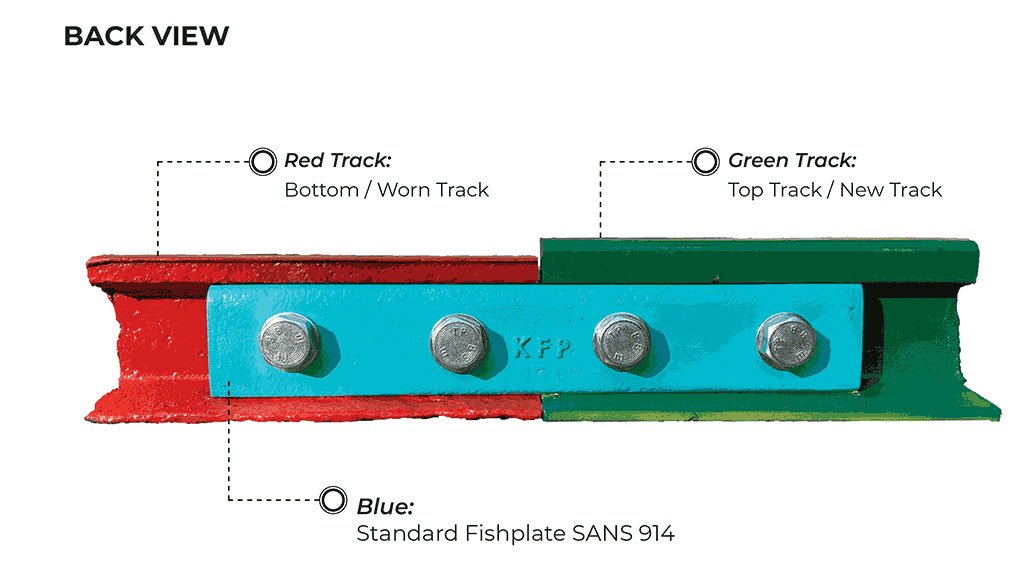

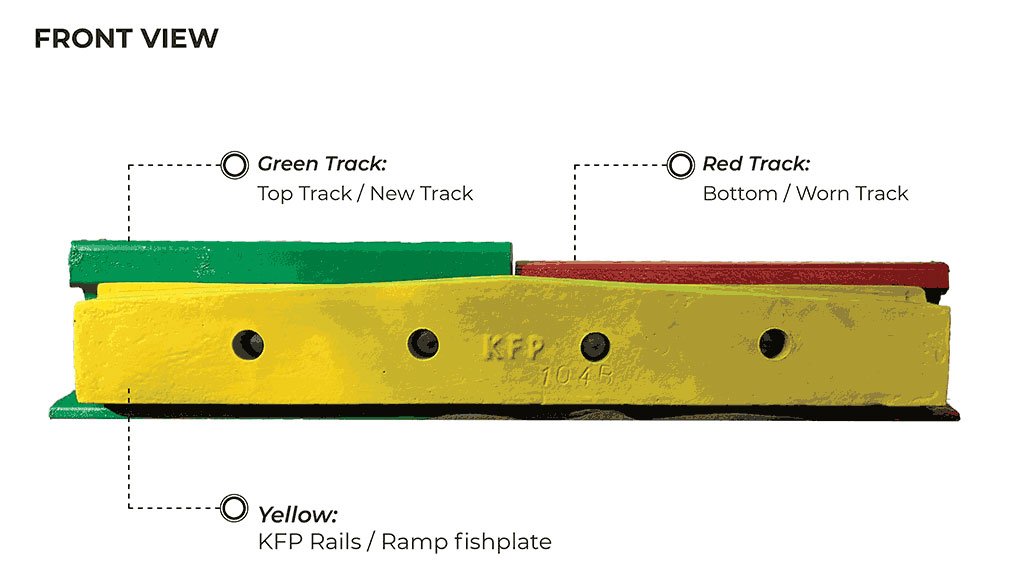

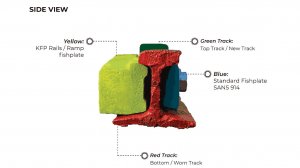

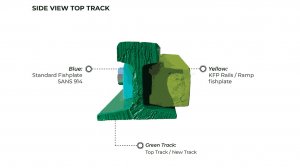

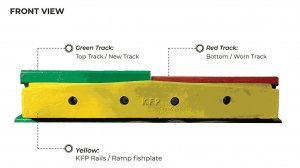

KFP has designed and patented a practical, cost-effective and phased solution to address the issue using a tri-product approach, namely the Standard Fish^Plate, Ramp Ready Fish^Plate and Ramp Ready Accessory.

The Ramp Ready Fish^Plate, which has yet to be manufactured, is designed to be a more cost-effective solution, reducing the initial cost of the Ramp Accessory, which is a heavy block of steel and, therefore, “quite pricey”. Only the Ramp Accessory is subject to wear and replaced.

“The idea involves using the wheel flange to ride on the Ramp Accessory to lift the wheel over the rail joint. Before the idea could be disclosed to the mine, however, we needed to ensure our patent was in place,” notes Penn-Clarke.

Wooden models of the Standard Fish^Plate and the ramp were presented to the mine for comment, following which the mine immediately asked for trial castings for installation underground on the track where most of its derailments occurred.

The Standard Fish^Plate is used on the outside of the track, while the ramp is fitted to the inside of the track to make contact with the wheel flanges so they can ride up and down the ramp.

While development went “pretty well with no real challenges”, he reveals that KFP was asked by the mine to widen the ramp by about 10 mm, which resulted in new patterns, castings and items being issued for installation.

“The castings of KFP’s Standard Fish^Plate, Ramp Ready Fish^Plate and Ramp Ready Accessory were issued to the client in the beginning of June this year, about a month after KFP was initially approached by the mine,” says Penn-Clarke.

“We received feedback that the wagons now passed these joints without any problems or derailments,” says Penn-Clarke.

The mine recorded videos of the results and was expected to present its findings to the steering committee on June 28 and is still awaiting feedback.

“The mine informed us of about 2 000 problem joints where we presume our product would be needed. We wait in anticipation for an order,” states Penn-Clarke.

Made in Johannesburg using steel, iron and additives that are all locally mined and sourced, KFP’s fishplates are manufactured in accordance with SANS 914.

KFP is keen to export its fishplates to mining countries, such as the US, Brazil, Chile and Tanzania, and expects the expansive mining market in the US together with the favourable exchange rate to present the greatest potential demand for its affordable solution.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation