Linear motion solutions can enhance efficiency

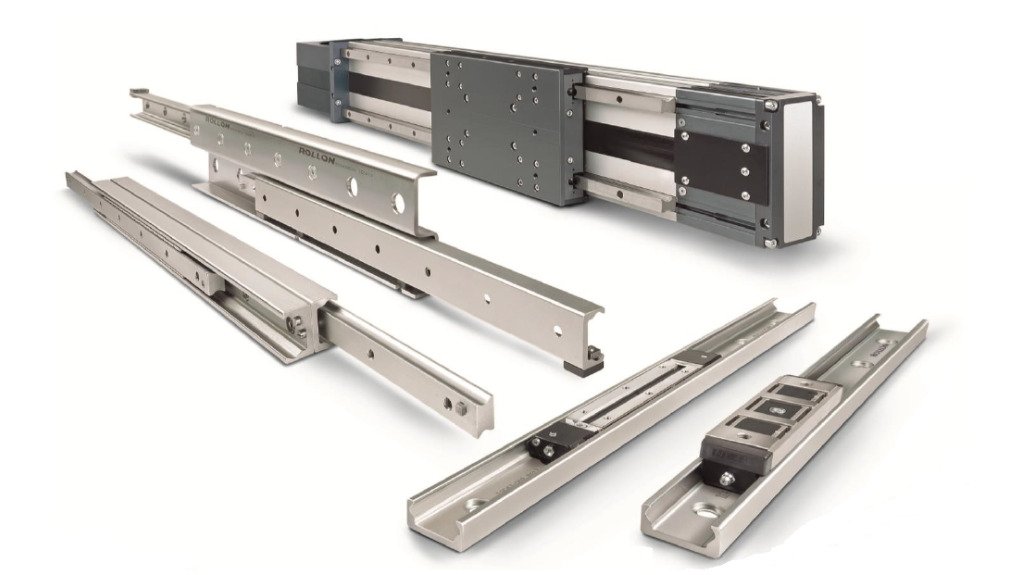

KEY TO PRECISION Functioning alongside compact ball screws that are locked onto a platform and linked to a servo motor, these linear guides allow for precise, high-speed linear motion with minimal resistance

Photo by BMG

By offering a comprehensive range of IKO Nippon Thompson’s linear guides, runner blocks and associated products, industrial equipment and services supplier BMG’s bearings division helps the paper, pulp and wood industry enhance efficiency.

The IKO components – which also incorporate rails, ball screws, bushings and shafts – are engineered to provide high speed, precision and durability, making them essential for industries that require smooth, controlled movement and long-term reliability.

For more that 47 years, BMG has been the exclusive distributor of IKO products in South Africa, and the company may see an uptick in demand, owing to “a growing trend of companies moving away from manual machine operation to specialised mechanisation”, explains BMG Bearings Division business unit manager Ziyaad Shaik.

BMG has invested substantially in expanding its product range to meet demand in standard and highly complex applications.

IKO’s linear motion system components are designed for applications that require “smooth, long-term performance”.

These components are widely used by original-equipment manufacturers, as well as in automation and advanced measuring systems, packaging, and precision manufacturing plants, adds BMG linear way, ball screw and precision bearings product specialist Leon Koekemoer.

He further explains that a lot of board manufacturers have their plants at the source of their raw materials. In other words, these manufacturers have plants at the plantations, which are often very far away from major centres.

“As such these customers are very attentive to the quality of the products that we supply them and prefer anything that [requires little to no maintenance]. Breakdowns in these remote areas can be very costly, outweighing the ‘savings’ made on procuring cheaper bearings and components.”

Shaik says the key to precision instruments are linear guides, which function alongside compact ball screws that are locked onto a platform and linked to a servo motor. This setup allows for a more precise high-speed linear motion with less resistance.

BMG’s IKO linear motion products have been carefully selected for their accuracy, smooth operation and easy integration into numerous applications, states Koekemoer.

“One of the most significant advantages of IKO’s linear motion products is their maintenance-free design, which significantly extends product life span.”

Further, IKO’s maintenance-free bearings are easily recognisable, owing to their blue plastic end pieces.

“These ensure that there is no need for lubrication, which translates into cost savings, as they eliminate lubricants, lubrication systems and downtime owing to premature bearing failures,” explains Koekemoer.

A key feature of IKO linear products is the C-Lube technology, which provides long-term, maintenance-free operation for up to 20 000 km, or five years.

Koekemoer highlights that, unlike competitors, which offer maintenance-free options as costly add-ons, IKO includes C-Lube as a standard feature. The C-Lube is built into the bearing without having to make any changes to its external dimensions, thereby ensuring a smooth motion without increasing friction.

This self-lubricating system also helps businesses significantly reduce the risk of contamination in precision applications.

These advantages make IKO the preferred choice for industries requiring long-term performance and reliability in demanding environments, says Koekemoer.

BMG also offers the custom manufacturing of ball screws to meet specific requirements. Whether based on customer samples or technical drawings, every component meets the exact specifications for optimal machine performance.

The company maintains a large stock holding of linear guides and rails to ensure fast availability for critical applications.

To further support customers, BMG offers failure analysis and technical support through phone calls, emails or site visits, as well as application-specific recommendations.

“Our specialists, trained by our suppliers, have extensive experience in diagnosing issues and providing solutions tailored to specific operational needs,” states Koekemoer.

By offering expert guidance and industry-specific solutions, BMG can ensure that customers acquire the most suitable IKO linear motion components for applications.

BMG’s exclusive distribution rights with IKO ensure access to Japan’s advanced linear motion technology, which has a reputation for “engineering excellence and innovation”.

Further, sourcing from world-class manufacturers, such as IKO, enables BMG to ensure that customers receive components that deliver on international quality, reliability and performance standards, Koekemoer adds.

BMG also collaborates with other top-tier bearing manufacturers, including machinery manufacturing company NSK and manufacturing company NTN, ensuring a diverse portfolio of high-performance solutions.

The company guarantees consistent product availability, as well as industry-leading quality standards, owing to its relationships with global suppliers.

“This strategic approach not only enhances BMG’s reputation as a trusted supplier but also reinforces our position as an industry leader,” notes Koekemoer.

Further, “our total solutions service allows companies to enhance machine performance, and maximise [their] return on investment”, concludes Shaik.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation