Open control system reduces conveyor’s maintenance costs

OPEN SYSTEM Layer Seven Automation’s aim was to create centralised control architecture that would increase the efficiency of the system and reduce costs

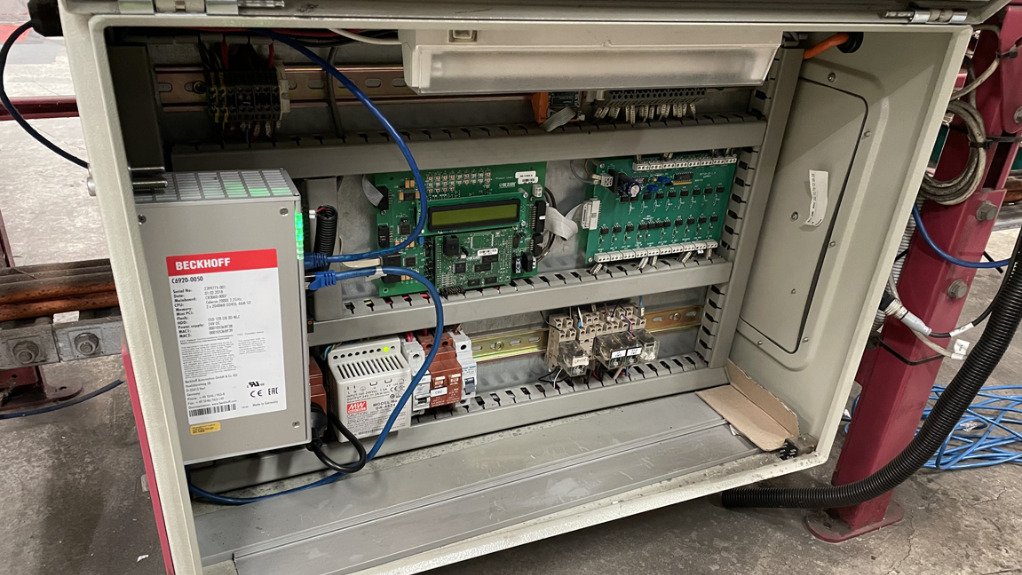

Photo by Beckhoff

USEABLE CONVEYOR An evaluation of the conveyor lines, which comprised a total length 700 m and 28 distribution centres, revealed that the mechanics of the main conveyor belt were still useable but the control system needed to be replaced

Photo by Beckhoff

With frequent malfunctions occurring along the conveyor line of a leading Australian office equipment supplier’s main distribution centre, its management team commissioned automation company Layer Seven Automation to develop a concept to modernise its warehousing system.

The system comprises a variety of conveyor lines with a total length of 700 m and 28 distribution stations.

An evaluation of the conveyors revealed that the mechanics of the main conveyor belt were still in a usable state but that the control system needed to be replaced.

“One of the disadvantages of the conveyor system was its proprietary structure. Every part had to be purchased from the manufacturer, which would have made it even more difficult to expand the system,” states Layer Seven Automation chief engineer Lucky Thommadura.

As a result, it was decided that an open system, based on off-the-shelf products would be configured. Thommadura notes that this would offer a futureproof solution and reduce maintenance costs.

The original system configuration was based on one controller and one barcode scanner for each distribution station. Layer Seven Automation’s aim was to create a centralised control architecture that would increase the efficiency of the system and reduce costs.

The barcode scanners at each station are essential for recording the contents of the boxes. As such, Layer Seven Automation opted for scanners that can be configured through an EtherCAT interface and use integrated input/outputs for simple control functions.

The inputs are used to detect the boxes through optical sensors, for example, while the outputs are used to activate the switches or pushers according to the destination station.

First a single distribution station was converted, and its scanner was connected to a C6920 control cabinet Industrial PC, from automation company Beckhoff, through EtherCAT.

Following successful tests, all 28 stations were migrated in stages and networked with the C6920 in a linear structure – a daisy chain.

“The technicians of the logistics company and I were surprised by the compactness of the solution, the fast update rates of the EtherCAT network and the overall controller,” comments Thommadura.

The barcode on the box must be scanned and forwarded to the Industrial PC through EtherCAT. There, the application determines whether the switch of the corresponding station needs to be activated and sends this information back to the barcode scanner through EtherCAT.

Thommadura states that the Beckhoff Industrial PC manages the extensive calculations in around 100 µs, which is “phenomenally fast”, but that the company still has reserves.

While there had not yet been a network failure when the release was published on the Beckhoff website, Thommadura notes that carelessness can quickly cause a cable break and, therefore, result in a failure of the entire system.

He adds that a shutdown of this kind would have a significant impact on productivity, especially in such a large-scale logistics installation. Consequently, there are concrete plans to implement cable redundancy, which is easy to retrofit with EtherCAT.

“We knew that all of this would be new to us. But when I discovered how EtherCAT works, what an Industrial PC is, and how easily we can combine Windows with a virtual programmable logic controller, it all made sense,” explains Thommadura.

He adds that the virtual machine enabled him to test the programme through a laptop from home, at work or on site.

Moreover, the fact that the TwinCAT is integrated in visual studio was another reason for the chief engineer to invest in Beckhoff and EtherCAT.

“I really believe that this is the way automation technology needs to go – away from closed systems with Ladder Diagram programming and outdated signal processing. We need to take established software design and architecture practices and combine them with automated testing [to] deliver our solutions more effectively.”

Layer Seven Automation adds that a major advantage of computer-based control is that the control architecture can easily integrate with existing systems.

Thommadura elaborates that many IT departments have very strict security requirements, but “Windows is always easy to integrate”.

He says that the firewall, security settings and global user administration have made the work much easier.

The option to use Windows has also enabled Layer Seven Automation to combine its own programmes with TwinCAT. For example, a structured query language database was integrated through TwinCAT 3 Database Server – TF6420 – which archives the details of a box every time it is scanned.

This action is permanently recorded and logged in the TwinCAT 3 EventLogger. In addition, a dedicated message queue was created, which uses the automation device specification (ADS) protocol to extract data and ultimately link it to the RabbitMQ message broker software.

Thommadura concludes that, “ADS technology from Beckhoff offers almost unlimited possibilities. We use ADS to collect the recorded volumes of data and distribute them both horizontally and vertically. It can also be used to easily integrate almost any MES or ERP system”.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation