Platinum group metal poised to help protect world from growing water pollution threat

PGM-using MatiTech MD Mike Bowley interviewed by Mining Weekly's Martin Creamer. Video: Darlene Creamer.

Platinum group metal helping to treat water sustainably.

Platinum group metal helping to treat water sustainably.

Platinum group metal helping to treat water sustainably.

JOHANNESBURG (miningweekly.com) – Platinum group metal (PGM) is once again coming to the fore as a mineral resource that goes the extra mile in protecting a threatened global environment.

The latest indispensable commodity that is poised to be shielded by PGM, which has been safeguarding the air of cities from vehicle exhaust fumes for many decades, is drinking water, which is under increasing pollution threat. (Also watch attached Creamer Media video.)

Coming to the rescue now is PGM-catalysed hydrogen peroxide, which is providing the world with an opportunity to treat water chemistries that are hard to break down.

The biggest benefit of the ultra-pure hydrogen peroxide that PGM is helping to generate is that it is green, clean and environmentally protective.

The base elements of hydrogen peroxide are water and oxygen, which is akin to water being the sole by-product of PGM-catalysed green hydrogen-driven fuel cells that power trucks, trains, buses, bakkies, ships, factories, offices, homes and so much more.

Where water is in a constant loop or stored, pathogens build up and it is hydrogen peroxide that is able to remove that threat sustainably.

Johannesburg-based MatiTech has introduced the PGM-catalysed hydrogen peroxide generator – the HPGen – which enables the safe and easy on-site manufacture and roll-out of hydrogen peroxide for use in water treatment.

South African-mined PGM is used in the electrochemical stack of MatiTech’s HPGen.

Interestingly, MatiTech has been incubated by global venture capital initiator AP Ventures, which is supported by South African PGM-mining companies as well as South Africa’s State-owned Public Investment Corporation (PIC).

MatiTech’s forward surge is taking place at a time when global alarm bells are beginning to be rung across the world owing to the increasing level of pollutants doggedly positioning themselves in the world’s water sources.

Because the hydrogen peroxide is generated on-site, where there is no need for additives, it is extremely pure, which, in itself, makes it ultra-effective in water treatment applications.

“We then combine this new technology with existing technologies, such as ultraviolet disinfection, ozone treatment, reverse osmosis filtration systems, and our ability to treat organic chemistries and organic organisms sets us apart from any other water treatment facilitator,” MatiTech MD Mike Bowley emphasised during a Zoom interview with Mining Weekly.

“With the increasing level of pollutants that we are seeing in our water sources, the technology we’re currently using cannot continue to be used.

“We have to find an alternative and hydrogen peroxide is that alternative. When we see high levels of organic pollutants in raw water sources, chlorine derivative disinfection byproducts create carcinogenic byproducts, which unfortunately we’re seeing happen in South Africa,” said Bowley.

“There are examples of this, and the hydrogen peroxide creates the opportunity to remove that chlorine-based technology and use hydrogen peroxide.

“This is the future of water treatment, and not just in South Africa, but globally. We're seeing research done on it by the Environmental Protection Agency in the US. In Australia, they're doing research on using hydrogen peroxide in water treatment, and, as MatiTech, we’re driving that force here in South Africa and in Africa.”

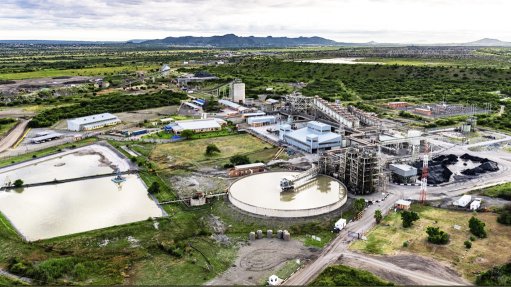

Regarding HPGen technology being used on a local mine site, Bowley added: “In essence, the PGM has come home, if you will, on this mining site. It was mined on this site, we’ve included it in a technology, and we’re using this technology to provide drinking water to the mine. It's a vastly important technology that could increase the use of PGM globally.”

Mining Weekly: What are the future problems and issues relating to potable water treatment, affecting not only remote sites but all water treatment plants?

Bowley: The biggest problems that we are seeing with water treatments and drinking water in South Africa are the increasing level of pollutants in raw water sources, which can be anything from a river, a dam, and even the boreholes that people in South Africa use quite readily to access groundwater sources. We’re seeing pollutants coming into these groundwater sources that are extremely difficult for our water treatment industry to treat. We are having to change how we think about treating water. Most of our water treatment plants are remote, so getting the products and the chemistries that we use in water treatment to these sites is extremely difficult with our infrastructure in South Africa. What we're also finding are new types of pollutants in the water sources. We have the ‘forever’ chemistries that are spoken about, and we’re finding pharmaceuticals, pesticides, which are extremely difficult to break down from a water treatment perspective.

How does MatiTech address these issues relating to potable water treatment?

We look at applying innovative new technologies to these problems and the HPGen provides us the opportunity to use hydrogen peroxide in water treatment safely and easily, because the peroxide is now manufactured on-site, rather than having to ship it in, in extremely high concentrations, which then had to be decanted or watered down for it to be used in water treatments. But the hydrogen peroxide generator manufactures peroxide on site and we can introduce that ultra-pure hydrogen peroxide directly into the water treatment process, without any need for additives.

For remote mining sites, what are the benefits of a MatiTech water treatment plant?

The biggest benefit that we see is being able to be decentralised. Remote mining sites struggle to get chemistries to site that they need in their water treatment processes. The HPGen has very few inputs. For us to produce the hydrogen peroxide, we need a water source, electricity, and oxygen from the air. We don't even need to provide oxygen as an input. We take it straight out the atmosphere, and we are then able to manufacture hydrogen peroxide. We’re removing reliance on a supply chain. The systems that we design are also autonomous. We remotely monitor the systems and we then are able to adjust them based on the inputs that we receive from the site. We also create dynamic systems and what that means is that if the raw water source becomes more pollutant in whatever way, we’re able to up the dosages by looking at what we are treating. We look at the raw water source and dose accordingly. That helps remote sites, which still need skilled water technicians, but we take over that responsibility for mining sites, wherever they are positioned, throughout Africa. We can position one of our systems on site, manufacture it in South Africa, and transport it to these sites, wherever they are in Africa.

Is providing constant reliable potable water the only benefit that the MatiTech systems can offer a remote site?

Not at all. The peroxide we produce is able to be used in multiple opportunities. We can use this in irrigation water, where we are treating plant pathogens. If there's a local community that's in the area, or host community, we could treat the irrigation water they’re using to irrigate their crops. We’re able to use the hydrogen peroxide in what we call hard surface disinfection for the hospitality sector and for clinics. You can use it to wash down surfaces. If you think about the possibility of a spillage, within hours, the peroxide breaks down into water and oxygen, and you have nothing hazardous re-entering into the environment. We see multiple opportunities for this peroxide and for our solutions. We’re even applying this into fisheries, because through that process of creating oxygen, we're able to oxygenate the water for fish and help fisheries to increase the levels of oxygen in their hatcheries. We see multi benefits, but our core focus is on potable water, because of the dire need for it in Africa.

Where else can the HPGen technology be used and how can the systems benefit these other markets?

The core technology was actually created with advanced agricultural hydroponic systems in mind. Peroxide is extremely efficient in breaking down the slime that you find blocking irrigation pipes and blocking irrigation nozzles, so that's where we can use the HPGen and the peroxide technology. We also then have moved into data centres and cooling towers, where you have things like Legionella building up in water reticulation systems. Where water is in a constant loop or stored, you have this problem of build-up of pathogens, and the peroxide that we use then goes into disinfecting the water to remove that threat. The biggest benefit that we also see is that this technology is able to be positioned wherever there is a need for an oxidation process. You could use this to take the sulphur out of wastewater plants, and in effluent treatments, it’s multifaceted. We have positioned one of our solutions on a platinum mine - the product coming home is a PGM that we use in the HPGen technology. The PGM is in the electrochemical stack, which then produces the hydrogen peroxide. The PGM is mined in South Africa. We are then using this metal to now treat the water and provide the mine with potable drinking water.

FAR-REACHING POSSIBILITIES

MatiTech know-how, which it has been propagating since its inception in 2021, centres on crafting bespoke, site-specific water treatment solutions for diverse applications, ranging from potable water treatments to agricultural and industrial water needs.

As reported by Mining Weekly last month, it is the view of AP Ventures founding partner Kevin Eggers that hydrogen peroxide technology is going to have a profound water impact in South Africa for years to come.

Opportunities to make local use of hydrogen peroxide are being pursued and early conversations are under way with vineyards looking to treat their water.

A trial has taken place in Napa Valley, in the US, which is being leveraged to find local applications in the Western Cape. There are also a series of commercial sales in agriculture across the country, in the North West and in George.

“We’re very grateful for the support we’ve received from Anglo American, Impala Platinum and the PIC, three very supportive LPs, who share our strategic ambition to develop hydrogen projects and opportunities globally in terms of the meaningful impact that should have and will have on PGM but also domestically in terms of the opportunity within South Africa, which has abundant wind and solar renewable energy resources,” said Eggers in the earlier interview.

Eighty per cent of the investments of AP Ventures are in the northern hemisphere, with the remaining 20% going into ‘other’, which takes in Australia, New Zealand and South Africa.

The portfolio of the venture capital company is focused mainly on hydrogen’s role in decarbonising energy and industry.

Since 2013, its investments have gone into technologies that unlock the hydrogen value chain to enable the transition to sustainable energy.

Investments are in hydrogen production, storage and transportation as well as hydrogen applications that address the structural constraints affecting mining, transportation and heavy industry.

Targeted are early-stage technology companies with global mandates that address the UN Sustainable Development Goals.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation