Modular Mining Systems honours Palabora Copper for using its solutions for 30 years

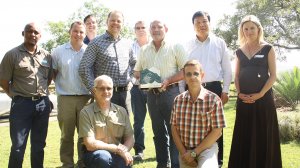

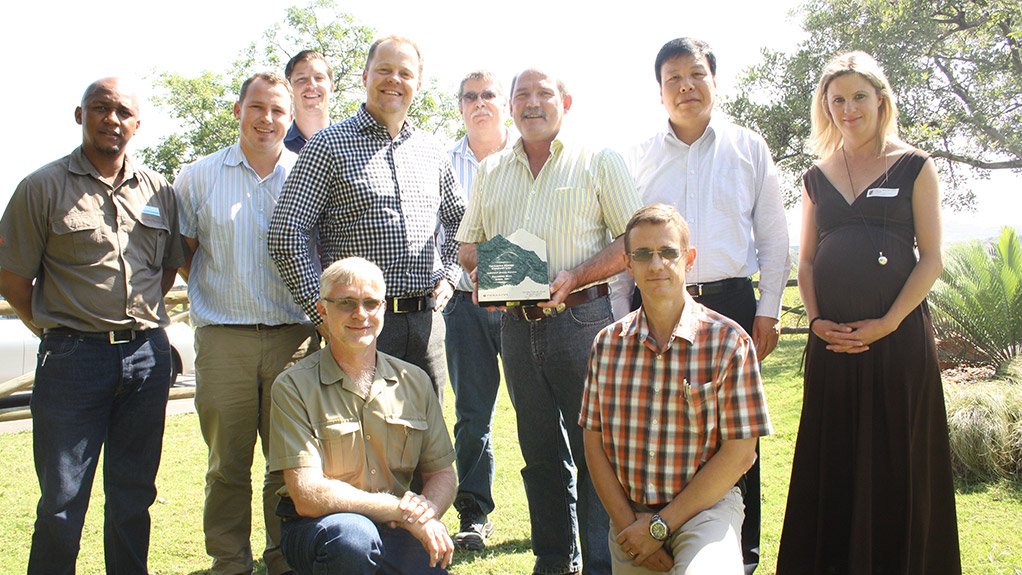

AWARD HANDOVER Palabora Copper mining division GM Johan van Dyk with the client achievement award presented to it by Modular Mining Systems on October 29, 2014

Mine management solutions provider Modular Mining Systems last month presented a long-term client service award to refined copper producer Palabora Copper (PC), a subsidiary of Palabora Mining Company (PMC), which extracts and beneficiates copper and other by-products in the Ba-Phalaborwa area, in Limpopo.

The copper operation comprises an underground mine, a concentrator, a copper smelter with anode casting facilities and an associated acid plant, an electrolytic refinery tank house, a rod casting plant, a magnetite separation plant and by-product recovery plants. The vermiculite operation comprises an openpit mining operation and a recovery plant.

Palabora Copper has been producing copper in South Africa for more than 50 years, initially as a large openpit operation and then as an underground block cave operation in 2002, known as Lift I.

PC has been using Modular Mining Systems solutions for almost 30 years, since it was an openpit mining operation, with the software subsequently also piloted in PC’s underground mine.

Speaking at the award handover in Palaborwa, Modular Mining Systems (MMS) Africa MD Lourens du Plessis thanked PC for being a valued long-term client of its patented Dispatch fleet management system. “We wish to continue this relationship with PC in its endeavour to develop the planned Lift II project.”

He added that the partnership with MMS was mutually beneficial, as much technology and innovation had been developed by partnering with our customers such as PC.

“Our aim is not to sell a system, but instead to partner with our clients to develop something new, especially in the underground mining space, where the correct mining methods are becoming increasingly important, as one cannot always succeed in developing value-adding technologies off-site, or without input from a mining house,” said Du Plessis.

PC mining division GM Johan van Dyk tells Mining Weekly that the award is significant, as it recognises that the partnership involves developing and improving the system from its inception and throughout the change from openpit to underground.

“MMS has ensured that we can operate by using its software, as we depend on getting a good enough grade to mine,” he says.

Using Dispatch software has resulted in increased productivity and production rates and improved management of rates, as well as the improved use and management of equipment for PC.

PC produces about 60 000 t/y of refined copper, which meets most of South Africa’s copper requirements, with the balance being exported.

PC Operations

Mining Weekly reported in August that a R9.3-billion block cave mine development project at PC’s mine was awaiting shareholder approval and was expected to increase the mine life by another 20 years to 2033.

A bankable feasibility study on the planned Lift II project had been undertaken, which PC growth division GM Nick Fouche said had provided a sound technical and positive business case to proceed to full execution.

“A bankable feasibility study was completed in May and presented an option, at a 90% confidence level, to develop a new Lift II mining footprint 450 m below Lift I, which will ensure a continuation of copper mining until 2033.”

He added that about R2-billion had been spent on the development of a twin decline and supporting engineering infrastructure as part of an early works programme.

This had ensured critical access to the undercut and would enable the Lift II production level to be ready for construction.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation