Weba Chutes take Africa in their stride

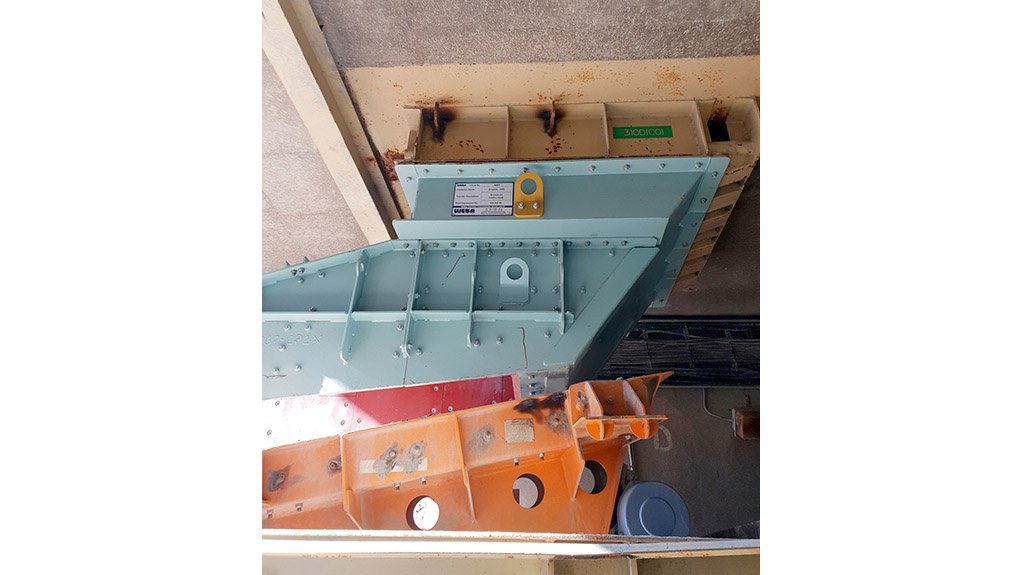

A custom engineered Weba transfer point solution being installed at a diamond mine in Botswana

Weba chutes have been operating successfully at Damang gold, one of the largest gold mines in the world, since 2010

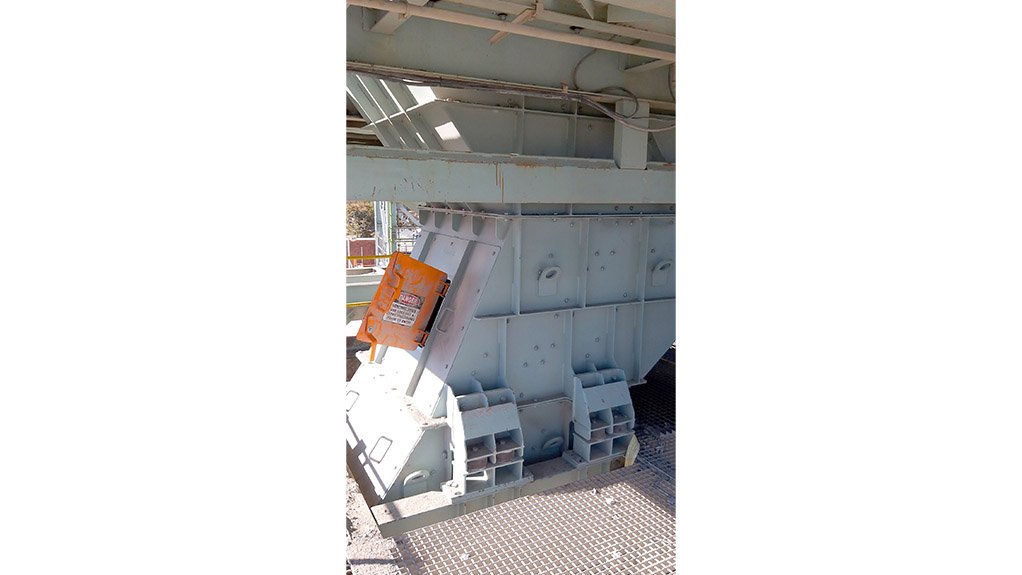

Weba chute systems at Frontier Mine, on the Zambia/DRC border

Custom engineered Weba chutes play an important role at Letseng diamond mine in Lesotho

Weba Chute Systems engineers bespoke transfer point solutions for specific applications

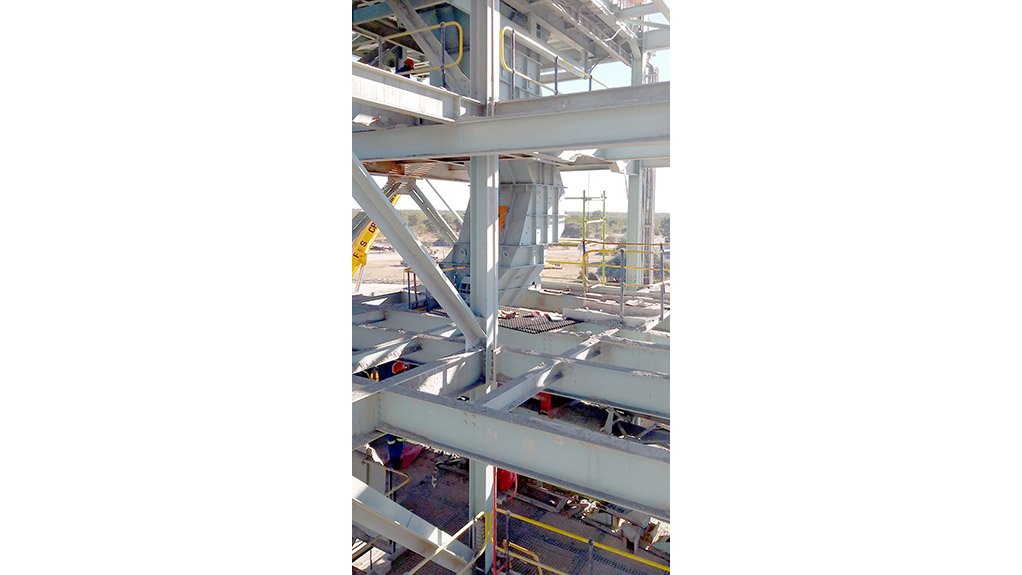

Weba Chutes installed at the Zimplats Ngezi platinum mine in Zimbabwe

Weba Chute Systems has proved its ability to custom engineer transfer point solutions across Africa

This article has been supplied.

With its custom-designed transfer point solutions at mines across Africa, Weba Chute Systems has proved its chutes in commodities from platinum to diamonds to gold, coal and copper.

In addition to mining hotspots including Ghana, Mali, the Democratic Republic of Congo (DRC), Zambia, Zimbabwe and Botswana, Weba Chute Systems have been installed in countries like Tanzania, Mauritania and Eritrea. Authorised Weba Chute Systems agents are deployed to support customers in key countries, while technical experts from the company’s head office in Germiston, Gauteng, are on call to assist.

“Mines across the continent have recognised the value of our custom-designed chutes,” says Wade Vandenberg, Weba Chute Systems’ technical advisor Africa. “Not only do these operations gain the benefits of controlled material flow in their operations, but they experience first-hand how our engineering design extends wear life and reduces maintenance downtime.”

He highlights that better dust control – a key part of health and safety policies in the mining sector – is another important benefit that Weba chutes bring to an operation.

“Our state-of-the-art digital engineering design facilities and expertise makes use of the latest technologies to simulate the specific material flow conditions in each customer’s application,” says Vandenberg. “This allows us to apply our philosophy that no two chute designs are identical, and to scientifically accommodate exact flow characteristics into our design.”

Discrete element modelling allows close control over the flow of material through the chute. This minimises turbulence reducing the levels of dust created in the working area. It also cuts spillage levels, which in turn means a saving of valuable material and less time spent on cleaning activities.

“We work towards the ISO dust management standards, supporting our customers in managing health and safety in this critical area of transfer points,” says Izak Potgieter, systems manager at Weba Chute Systems. “Our testing measures dust down to 0,03 micron particles, to make sure that our designs meet stringent health-related targets.”

Flow control also creates more material-on-material movement to reduce wear on chute liners, ensuring longer liner life when compared to that of conventional chutes. Custom design and use of simulation technology allow for the wear life to be carefully predicted, based on operating conditions.

“Our technical expertise and solutions-oriented approach mean that customers can always rely on us,” says Vandenberg. “When we commission one of our chutes, it is part of an ongoing productivity journey with our customer, no matter where they are located.”

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation