Increased uptake of the Sandvik DD422i development drill in Africa

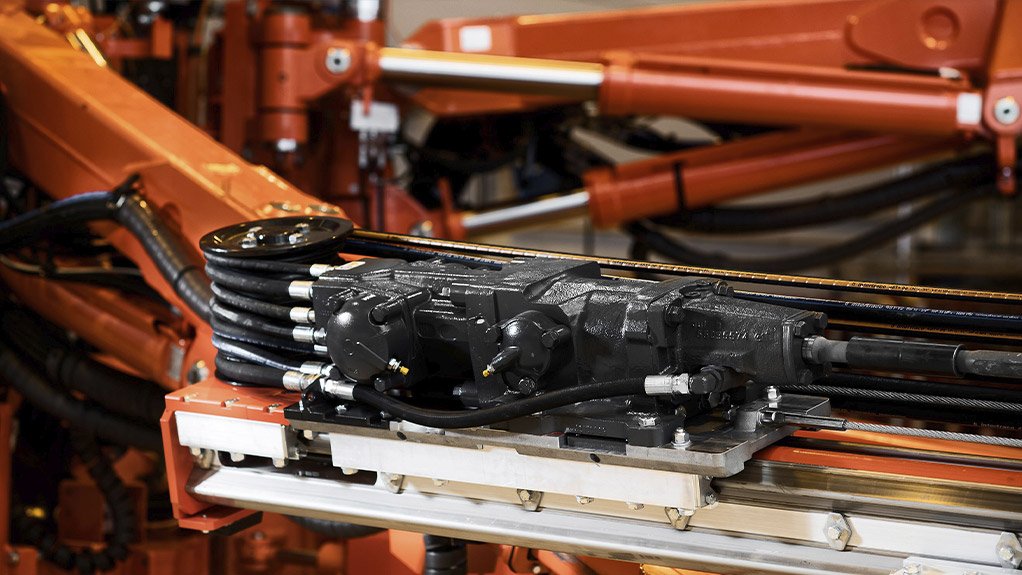

The Sandvik DD422i development drill rig features a full-face drilling automation system that ensures mines consistently achieve their optimum decline profiles, with minimal over- or under-breaking.

Saltiel Pule, business line manager for underground drilling in southern Africa at Sandvik Mining and Rock Solutions.

The Sandvik DD422i's high speed is made possible by the 25 kW RD525 drifter, the biggest in the Sandvik face drilling range.

The overarching differentiator is the iSURE®8 software, a computer programme for mining drill and blast process control.

As mines in Africa are constantly turning to modern technologies to run more efficient operations and improve safety, Sandvik Mining and Rock Solutions has seen renewed interest in its DD422i, the next-generation mining jumbo with the widest range of automatic drilling functions.

Having sold the first DD422i development drill in Africa to Black Mountain Mine in 2018, Sandvik Mining and Rock Solutions has seen a ramp up in sales in the past three years, with nine more units making their way onto local mining sites, averaging at least three machines per year.

Saltiel Pule, business line manager for underground drilling in southern Africa at Sandvik Mining and Rock Solutions, says the will be more than 10 units operating in southern Africa by the end of 2022. The Sandvik DD422i has proven to be a machine of choice for tier one mining contractors operating at high-production mines in South Africa, Botswana and Namibia.

“Traditionally, mines in Africa have always lagged behind their global counterparts in adopting new technologies,” says Saltiel. “However, the Covid-19 pandemic has accelerated the application of Fourth Industrial Revolution (4IR) technologies in the local mining industry, hence the ramp up in sales of the DD422i drill since 2020.”

The local mining sector, adds Saltiel, has in recent years started to witness increased digitisation of the work processes, as well as the adoption of automation and other innovative tools.

“The Sandvik DD422i made its global debut in 2016 as the founding platform of Sandvik’s next generation underground drills designed to meet the industry’s growing need for new 4IR technologies such as digitalisation and automation,” says Saltiel.

The overarching differentiator, says Saltiel, is the iSURE®8 software (Intelligent Sandvik Underground Rock Excavation), a computer programme for mining drill and blast process control. It produces all the data miners need for an optimal drilling and blasting cycle.

The recent Sandvik automation upgrade packages, the Teleremote drilling and drill bit changer, further enhance the Sandvik DD422i’s automation functions. Teleremote is a reliable and easy way to control the drill from a remote location.

Sandvik’s patented drill bit changer further improves drilling productivity by allowing the operator to drill a full round without leaving the cabin to change the bit manually.

“Another major talking point on the Sandvik DD422i is its high speed, made possible by the 25 kW RD525 drifter, the biggest in the Sandvik face drilling range. This is a significant improvement on the predecessor range’s HLX5 drifter, which offered 19,5 kW of drilling power,” concludes Saltiel.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation