Supplier champions energy efficiency across multiple sectors

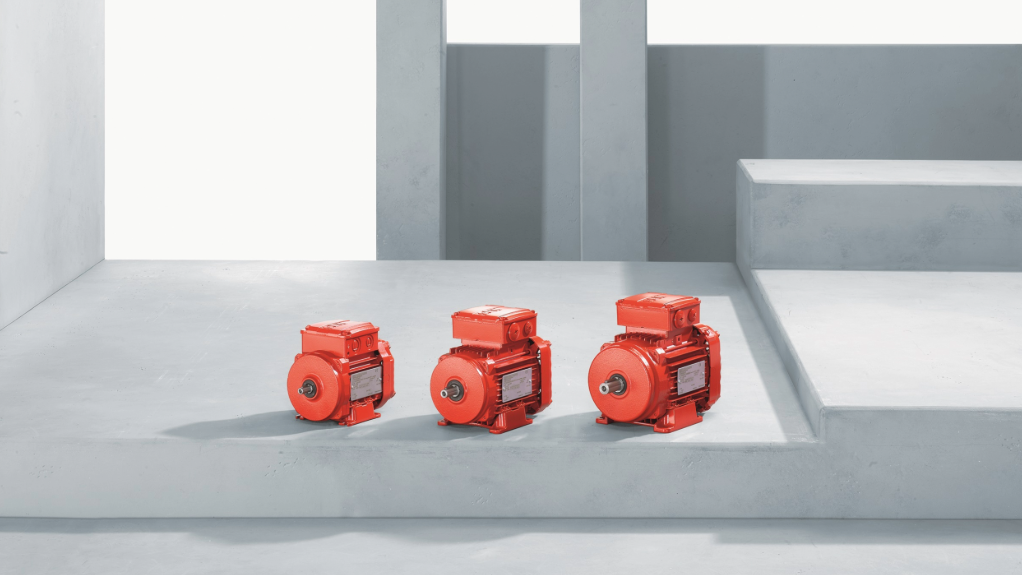

IE3 MOTORS The IE3 motors on offer from SEW-EURODRIVE can assist industry in improving efficiency and limiting the effects of increasing electricity costs

WILLEM STRYDOM As most electricity in South Africa still comes from coal, reducing consumption directly lowers carbon footprints

South Africa’s adoption of Minimum Energy Performance Standards (MEPS) mandates that all newly imported electric motors meet IE3 premium efficiency levels. Equipment provider SEW-EURODRIVE, however, has long been ahead of this curve, having standardised on IE3 motors more than eight years ago. The company’s commitment to sustainability ensured that its customers transitioned to the advanced technology without bearing additional costs.

SEW-EURODRIVE South Africa business development electronics manager Willem Strydom highlights that several industry sectors have been proactive in shifting towards energy efficiency. Rising electricity prices have driven industry to adopt IE3 motors, with SEW-EURODRIVE estimating that these motors consume 7% to 8% less energy compared to IE1 models. Strydom says that, when paired with variable-speed drives (VSDs), energy savings can reach up to 15%.

“Energy efficiency not only reduces operational costs but also aligns with companies’ decarbonisation goals,” says Strydom.

“As most electricity in South Africa still comes from coal, reducing consumption directly lowers carbon footprints.”

SEW-EURODRIVE supports its customers by conducting on-site energy assessments and product population surveys, at no cost.

“These evaluations identify inefficiencies, helping companies plan their transition to IE3 motors strategically and cost-effectively; the data collected also provides early warnings about potential equipment failures, reducing downtime risks,” he says.

To further ease the transition, SEW-EURODRIVE advises that customers prioritise upgrades in motor classes with lower stock levels, balancing replacements between larger and smaller motors for maximum impact. VSDs are often recommended to manage peak energy demands, reducing penalties and extending motor lifespans.

Looking ahead, Strydom believes the MEPS will accelerate the adoption of even higher efficiency standards, paving the way for IE4 and IE5 motors. SEW-EURODRIVE is already leading this innovation with its IE5 synchronous motors, which feature integrated permanent magnet technology and deliver up to 50% lower energy losses compared to IE3 models.

“SEW-EURODRIVE’s commitment to advancing energy efficiency is backed by our 300-strong global research and development team. We are already pioneering IE6 technology, setting new benchmarks in sustainability and performance,” he says.

With its forward-thinking approach and robust customer support, SEW-EURODRIVE continues to drive energy efficiency advancements in South Africa, helping industries meet sustainability and cost- saving goals.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation