Advanced wear life measurement technology for transfer chutes

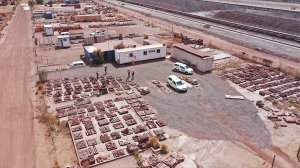

Planning, including stockholding of spare parts, can be done in advance with the reliability model in place

Chute inspections are being conducted to ensure the reliability model provides data as per actual chute conditions

All components are measured when standing inspections are done to verify the forward planning based on the reliability model

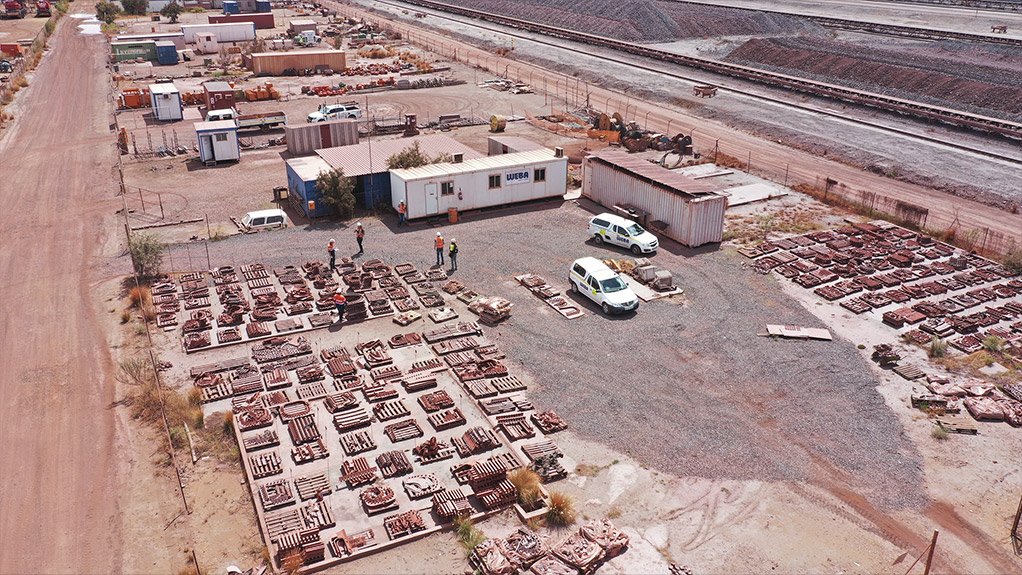

Components are installed once the wear rate is near 100% with a 10% confidence level still in place

Weekly inspections are conducted to ensure that conditions in the chute have not changed

Final inspections on components are done on site to ensure quality of product

This article has been supplied.

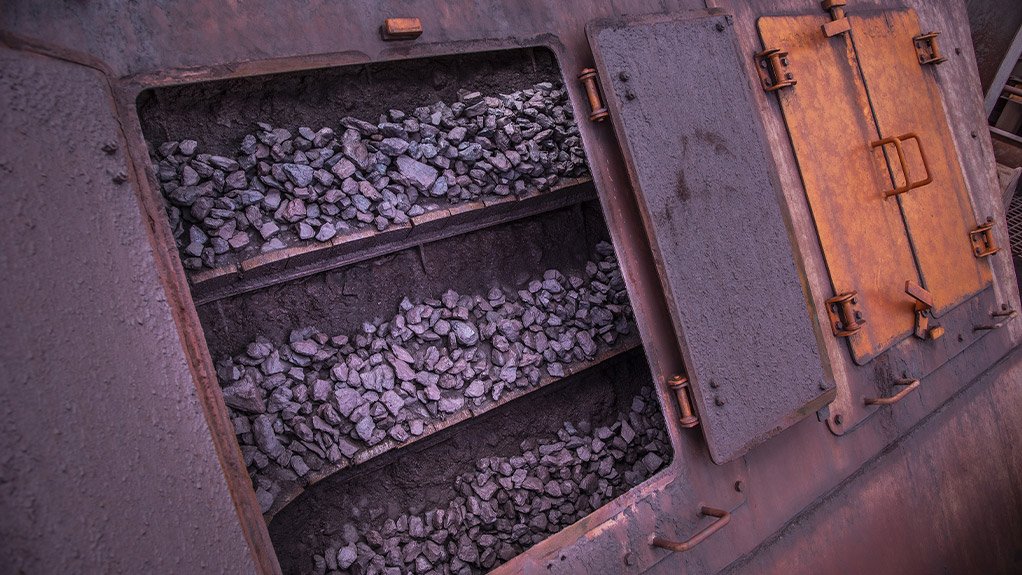

Transfer chute wear life measurement, an intricate process involving meticulous tracking of multiple components, is essential for enhancing uptime in materials handling applications — a direct contributor to operational efficiency. Izak Potgieter, Quality Systems Engineer at Weba Chute Systems, says that in its relentless pursuit of innovative solutions, the company pioneered a state-of-the-art reliability model which has over time gained momentum with many plants relying on this to predict maintenance requirements. The model embodies a specialised approach to the intricate task of chute wear monitoring.

"Our custom reliability model is adeptly engineered to encapsulate pivotal wear indicators for each chute,” Potgieter explains. “This level of precision enables us to accurately predict the wear life of individual components, from liners to lips and beyond."

For the model to function optimally, the integration of specific data is imperative—especially wear measurements obtained during regular inspections. Potgieter says that the discernment of wear patterns is of paramount significance, and that when furnished with this intel, plant operators are in a position to judiciously forecast which components necessitate imminent substitution.”

This capability is indispensable, and facilitates accurate and methodical planning, such as the timely procurement of pivotal components. It also strengthens preventive maintenance measures. The consequent elimination of unanticipated downtime safeguards a plant against disruptions and the ensuing loss of precious production hours.

“The capability to precisely predict component wear life has catapulted our maintenance paradigm to unparalleled heights, and this approach has received increased interest from customers, both those with Weba chute installations and other customer who are looking to changeover to more cost efficient transfer points,” he says. “While this tool is integral to our maintenance contracts, it merits mention that customers who do not have such agreements can still make use of this service from us.”

An auxiliary benefit of the reliability model is a comprehensive monthly dossier, providing stakeholders with timely alerts regarding maintenance requirements for each wear part within all chutes. The sophistication of this model is evidenced in its capacity to mirror differential wear levels across varied chute sections—especially those experiencing disparate impact levels. This granularity facilitates a targeted maintenance strategy, bolstering performance and longevity.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation