Common conveyor problems and best-practice maintenance approaches

Guy Fitt, National Sales Manager at Tru-Trac

Douglas van der Westhuizen, Technical Sales Representative at Tru-Trac

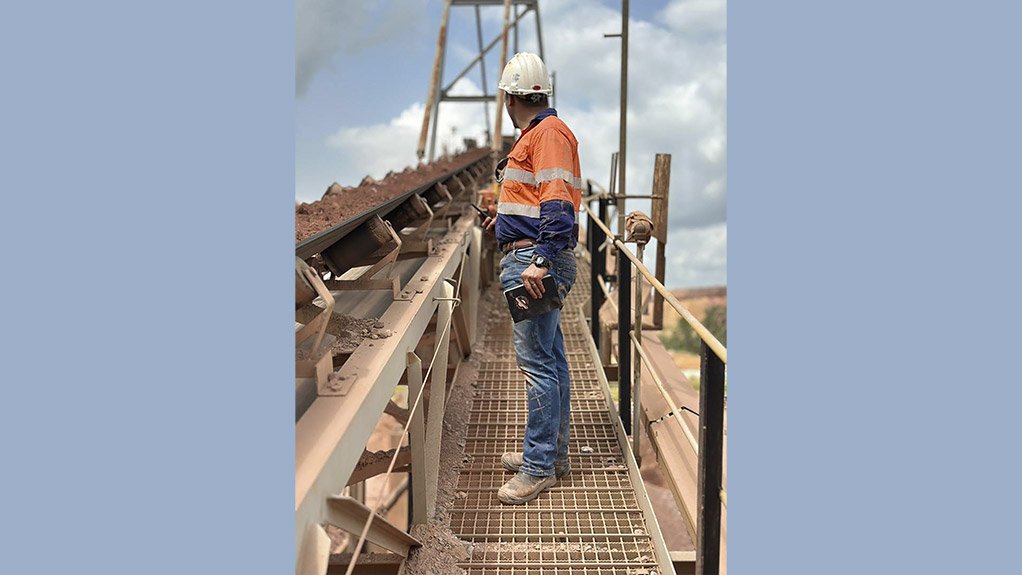

Regular inspections with Tru-Trac support help mines and quarries identify issues early ensuring safer, more reliable and more efficient conveyor operation

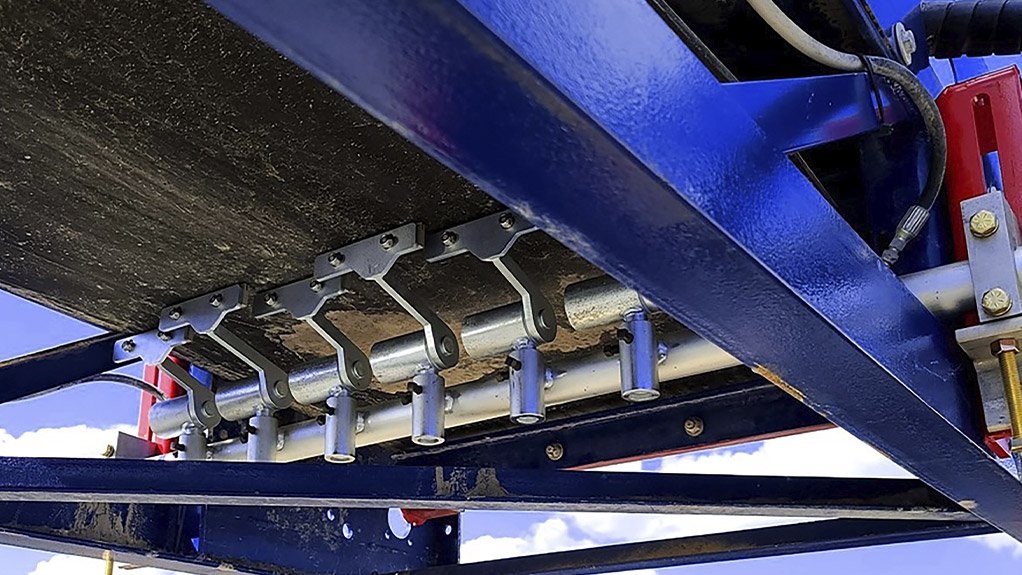

Tru-Trac trackers correct belt misalignment, preventing costly spillage and edge damage while keeping conveyor systems running smoothly

With Tru-Trac solutions conveyors stay centred, reducing downtime and protecting surrounding structures from unnecessary wear and damage

Tru-Trac scrapers combat carryback, keeping belts clean and improving overall productivity across the conveyor system

Tru-Trac’s ‘look and see’ inspection philosophy keeps conveyors running at peak performance by enabling early detection of issues before they impact production

This article has been supplied.

Lost production is a major direct cost that quarries and mines contend with when a conveyor system goes down. Some of the most common conveyor issues include belt misalignment, material carryback and rip events, amongst others. Drawing on decades of field experience, Tru-Trac’s Douglas van der Westhuizen and Guy Fitt outline some of the best-practice maintenance approaches to keeping conveyors at peak performance.

One of the most common causes of unscheduled downtime on conveyor systems is belt misalignment which often results in spillage, belt edge damage, damage to the structure, increased power consumption and increased labour costs. According to Guy Fitt, National Sales Manager at Tru-Trac, a specialist provider of conveyor components for the global mining and bulk material handling industries, misaligned belts will ultimately result in lost production, increased operating costs and safety hazards.

Douglas van der Westhuizen, Technical Sales Representative at Tru-Trac, says misaligned belts can also result in environmental issues by increasing material spillage and dust generation which can contaminate nearby ecosystems and water sources, lead to regulatory non-compliance and negatively affect the health of both workers and nearby communities.

Apart from belt misalignment, carryback is another common enemy in conveyor systems. Carryback directly reduces conveyor productivity by creating unscheduled downtime for cleanup, degrading components such as rollers and pulleys and causing material loss and leading to belt tracking issues that necessitate further maintenance. Carryback represents loss of product, which, over time, can add up to significant financial costs, especially in systems handling large volumes,” says Fitt.

Commenting on some of the best-practice maintenance approaches to keeping conveyors at peak performance, Fitt says that continuous inspection is one of the principal approaches to making sure that conveyor systems function optimally. With this approach, minor issues are identified early on before they escalate into major problems that lead to unexpected breakdowns. This minimises unplanned interruptions ensuring that material transport is uninterrupted and production schedules are maintained.

“Constant condition monitoring of conveyor components is one of the best practices in always ensuring correct belt tracking. It is essential to be fully aware of the basic characteristics of the different belt tracking components and for these to be employed correctly,” Van der Westhuizen says, adding that all the structural conveyor components such as pulleys, idlers, take-ups and the supporting structure should always be properly aligned at all times.

“In fact, these should be the principal areas of concern whenever trying to identify belt tracking problems. All pulleys, snub rollers, troughing and return idlers must be square with the frame parallel to each other, and also be level,” Van der Westhuizen concludes.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation