Optimising material transfer across industries with advanced handling solutions

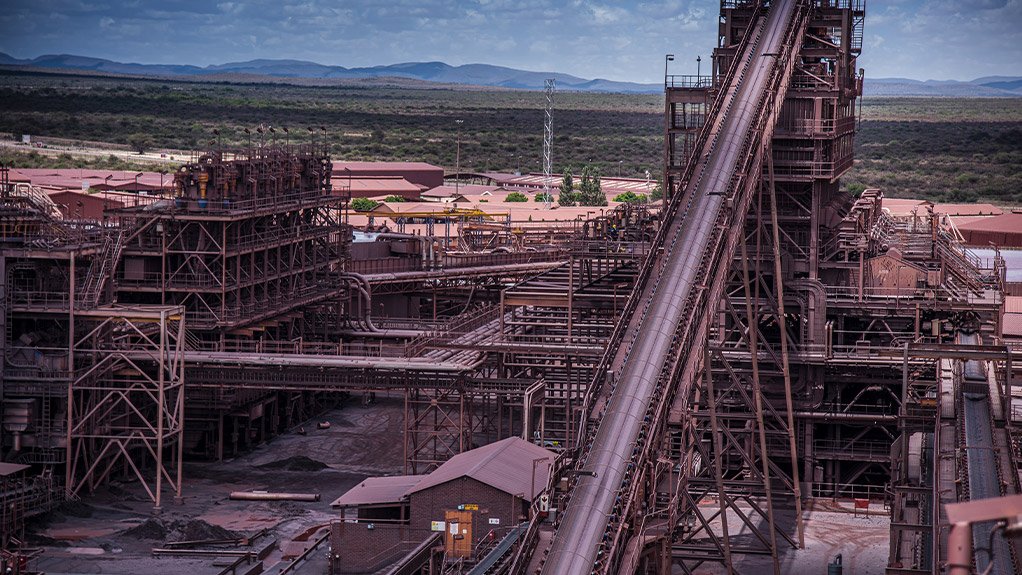

The feed conveyor discharge chute at an iron ore mine is designed for seamless material transfer, reducing spillage and dust while improving efficiency

Engineered for controlled material flow, the bifurcated chute prevents blockages and enhances process efficiency in bulk handling operations

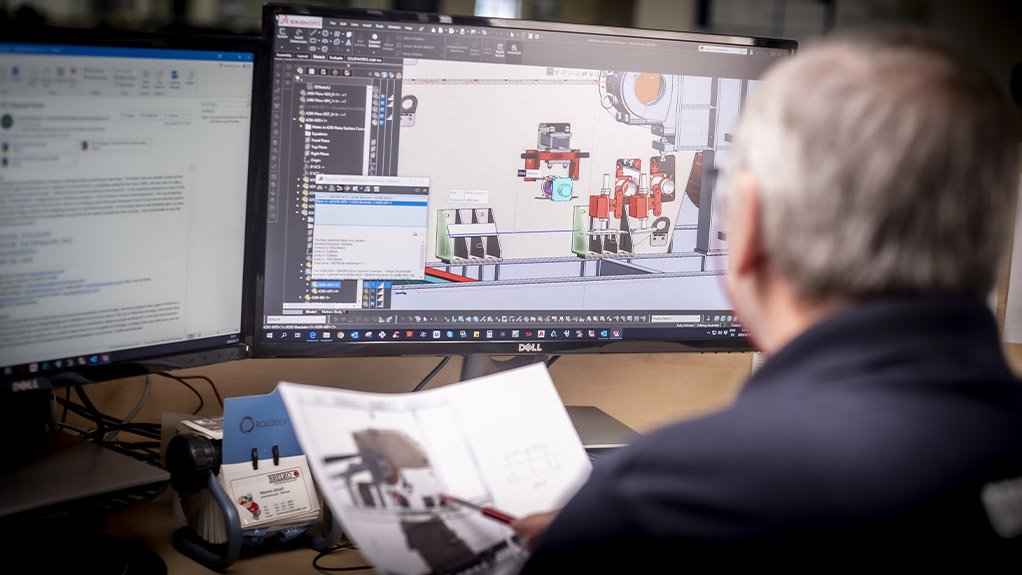

At Weba Chute Systems, a draughtsman reviews a design on CAD, ensuring precision and accuracy in custom-engineered transfer solutions

Dewald Tintinger, Technical Manager at Weba Chute Systems, discusses the science behind efficient material transfer and optimised flow dynamics

Designed to enhance productivity, the chute and conveyor belt system work together to minimise equipment wear and reduce operational downtime

With a focus on improving material distribution, the bifurcated chute showcases Weba Chute Systems’ expertise in precision engineered solutions

This article has been supplied.

Efficient material transfer is a critical component of any materials handling operation, regardless of the commodity being moved. Whether handling coal, minerals, aggregates or other bulk materials, achieving seamless transfer is essential for boosting productivity, minimising costs and maintaining operational safety. Weba Chute Systems, a global leader in transfer point technology, offers advanced solutions that address the unique challenges of materials handling, ensuring enhanced efficiency and reliability across diverse industries.

In materials handling operations, issues such as dust generation, spillage, material degradation and equipment wear can significantly impact productivity and operating costs. Weba Chute Systems employs a custom-engineered approach to mitigate these challenges. By focusing on optimised material flow and impact management, these systems reduce maintenance requirements, extend equipment lifespan and create safer working environments.

Dewald Tintinger, Technical Manager at Weba Chute Systems, explains that Weba Chute Systems adopted a scientific approach. “This,” he says, “is unlike conventional chute designs that often rely on high velocity material transfer. We use advanced simulation tools and our engineers analyse material trajectories, particle interactions and flow dynamics to develop solutions tailored to the specific needs of each customer’s operation. Our precision driven methodology ensures controlled material flow, minimising wear and tear on critical components and reducing downtime.”

Tintinger says that one of the standout benefits of these systems is their ability to suppress dust and prevent spillage. In industries where dust emissions can lead to environmental hazards and safety concerns, Weba Chute Systems’ solutions provide an effective way to optimise material flow while maintaining compliance with environmental regulations. The controlled flow of material also eliminates spillage and blockages, reducing operational disruptions and improving overall process efficiency.

“Customisation is a hallmark of Weba Chute Systems’ designs. Each system is tailored to match the unique characteristics of the material being handled including particle size, moisture content and flow rate,” he continues. It is this bespoke approach that ensures the transfer system performs optimally under real-world conditions, while its modular design allows for seamless integration with existing infrastructure, minimising installation time and costs.

Safety remains a key focus in materials handling, and Weba Chute Systems delivers on this front by reducing the risk of material ejection and incorporating features such as inspection doors and easy-access panels for safe maintenance. Additionally, the energy efficiency of these systems supports sustainability goals, as optimised material flow reduces power consumption and lowers an operation’s carbon footprint.

“We believe that our innovative designs and customer-centric approach makes Weba Chute Systems a trusted partner across industries requiring efficient material handling solutions. By addressing common challenges and delivering measurable improvements in productivity, safety and cost savings, these systems are helping companies to enhance their operations and achieve long term success,” Tintinger concludes.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation